Tel: 0086769-23187408

Email: [email protected]

Tel: 0086769-23187408

Email: [email protected]

By incorporating cut-resistant fabric into gloves, sleeves, and other protective garments, healthcare workers can carry out their duties with confidence, minimizing the risk of injuries and potential transmission of infectious agents.

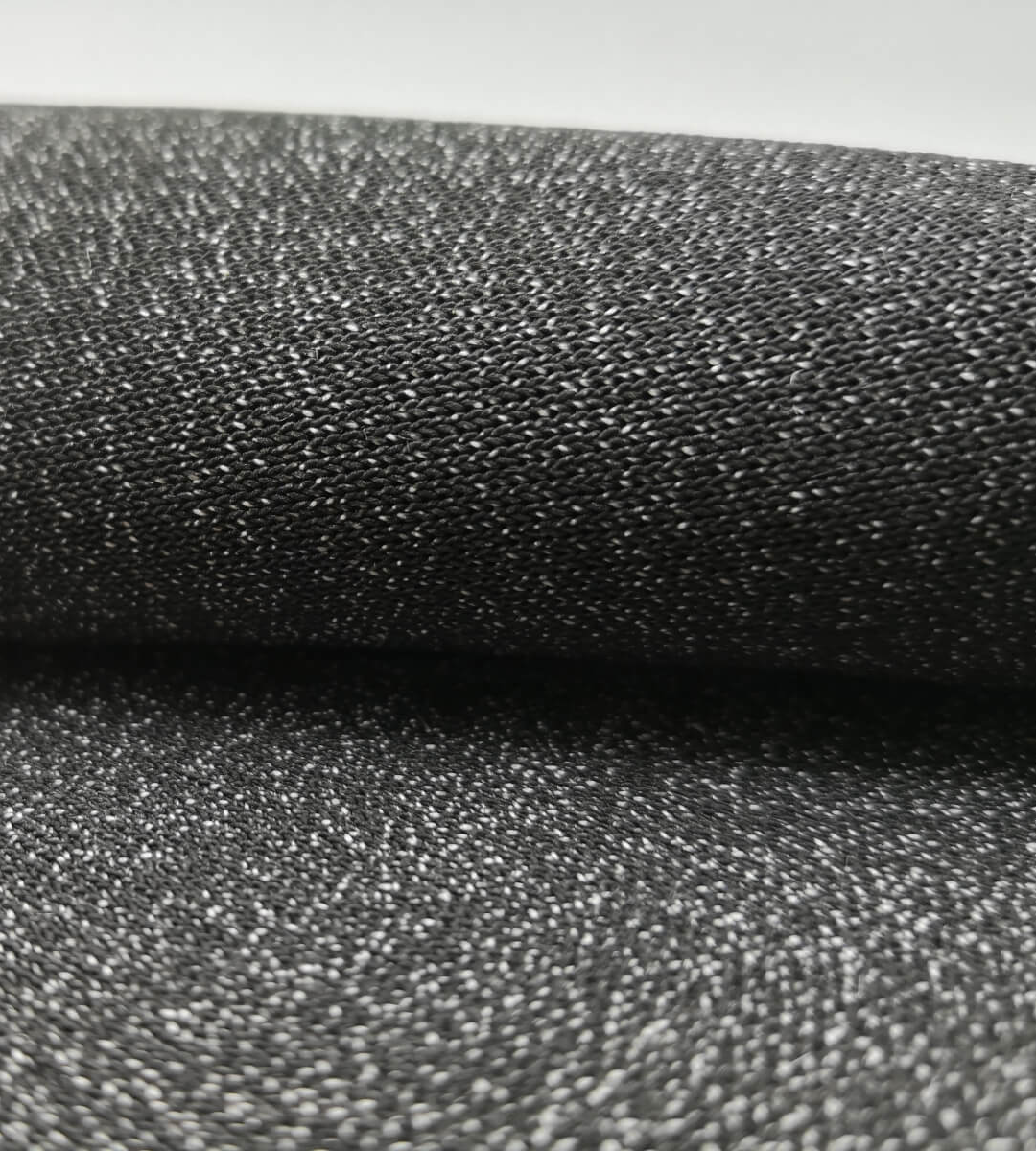

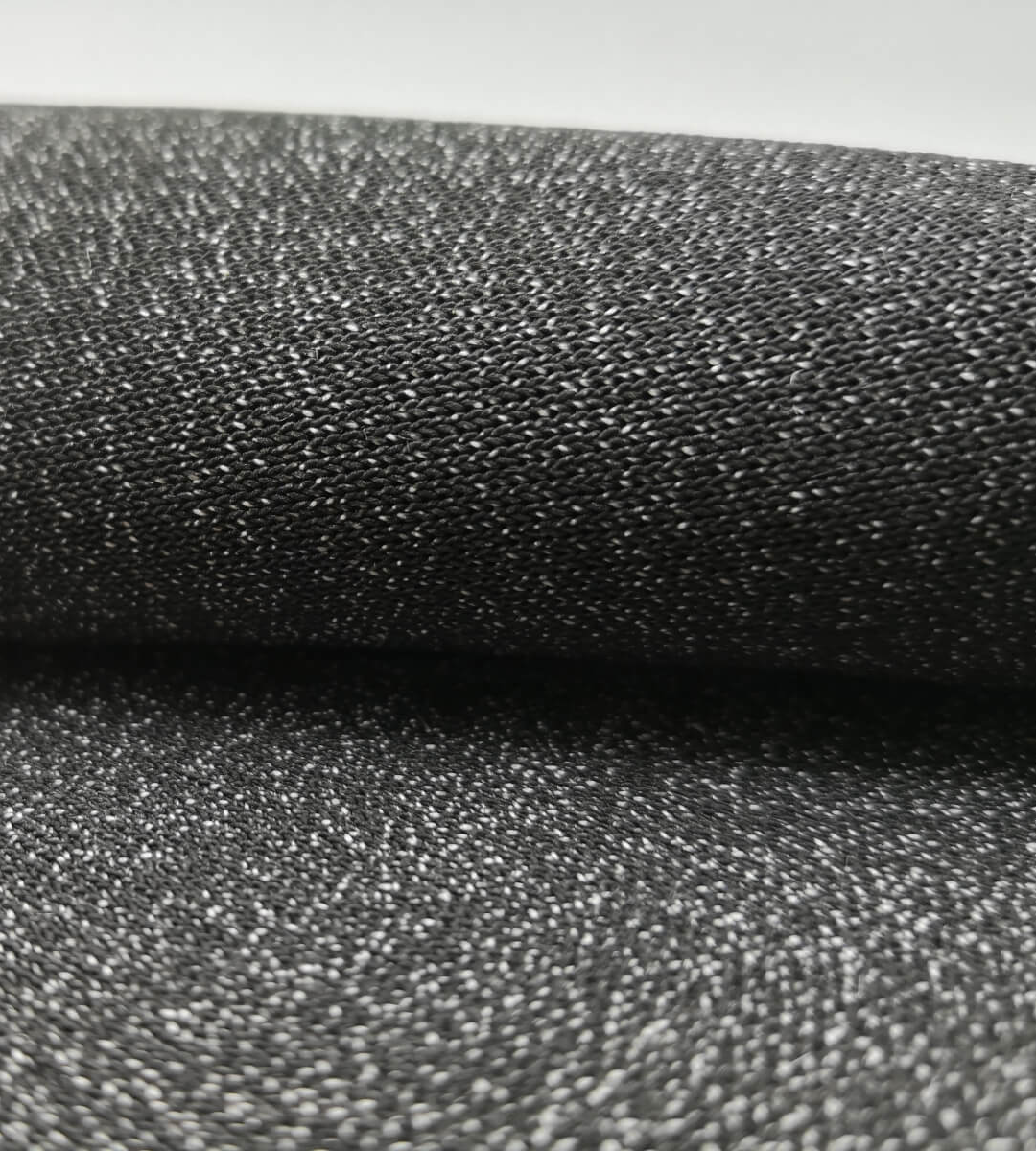

A number of industries currently use cut-resistant fabric, which is specifically designed to avoid cuts and slices. It has a good resistance to penetration and tearing that makes it ideal for those who work with sharp tools or machinery.

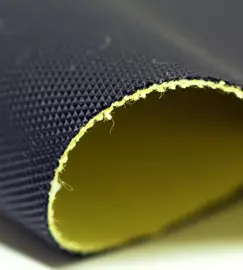

The unique features of cut-proof fabrics offer a number of advantages that set them apart from other materials. Firstly, the most important advantage is its cut resistance, achieved through a special weave and fiber combination. This amalgamation ensures better tensile strength thereby guaranteeing the fabrics are able to be cut without being compromised in terms of integrity.

Besides being cut-resistant, these kinds of textiles have other properties that are advantageous. It is usually light in weight and supple so as to move around easily while wearing personal protective equipment (PPE). Additionally, this material allows users to feel comfortable even when they are in their protective clothes because it breathes well.

Durability is another major benefit of cut-resistant fabric. Cut resistant materials are cost-effective because they must withstand constant usage and demanding environments. Being easy to clean and maintain adds up more points on its overall value.

Cut-proof fabrics find application areas in healthcare as well as food processing and manufacturing sectors among others. Very important for ensuring safety for individuals who frequently run into opportunities for cuts and slashes

Innovative weaving or knitting technologies combine tough fibers to ensure that tear strength in cut-resistant fabric is achieved. This feature of the fabric makes it less prone to tearing, thus keeping its structure intact even under extreme pressure and friction.

Tear resistance is very important in areas like construction, manufacturing and carpentry where workers are likely to come into contact with sharp tools as well as rough surfaces or abrasive substances. Cut-resistant materials prevent lacerations resulting from splitting or cutting which could otherwise endanger the lives of operators.

Cut-resistant fabrics also improve the safety of workers and prolong their useful life. Over time, it maintains integrity by not getting torn hence businesses do not have to replace them frequently and this saves money.

Therefore, rip-proof nature of cut-resistant fabrics enhances safety measures for workers as well as durability and confidence. Companies’ use of these materials in their safety guidelines would be a significant step in helping them avoid tears on their employees consequently reducing risks of injuries at workplaces.

NIZE offers advanced cut resistant fabric engineered for demanding industrial environments. Our material is designed to minimize injury risks and enhance product safety, making it an ideal solution for manufacturers of protective gear and safety equipment.

Cutproof textiles are made with hypoallergic fibers and materials that do not easily cause skin irritations or allergies. Therefore, it stays gentle on the skin even during long contacts thus minimizing chances of discomfort or negative responses.

An allergy-free nature of cut-resistant fabrics guarantees safety for workers in different sectors such as medicine, food processing, and production since most of them wear protective clothing for a long time. This is because they often have to wear protective clothes for extended periods which can lead to irritation or allergic reactions on their skins.

Non-allergic characteristics of cut-resistant fabric also promote general cleanliness and hygiene. The material has low concentration of allergens or irritants therefore reducing cases of exposure or cross contamination. This is critical in such industries as food processing or medical care where cleaning standards are very strict.

In conclusion, Non-allergic properties associated with cut resistant fabrics gives people with sensitive/allergic skins an additional advantage. Its hypoallergenic nature ensures comfortability by reducing the risk of irritation as it guarantees a more safe inclusive working environment for all.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

Cut resistant fabric provides reliable protection against cuts, reduces the risk of injuries, enhances worker safety, and improves overall productivity in high-risk work environments.

Yes, cut resistant fabric can be tailored to meet specific requirements, including different cut resistance levels, thicknesses, and garment designs to suit various industry needs.

While cut resistant fabric provides excellent protection against cuts, it may have limited resistance to other hazards like punctures, chemicals, or heat. Additional protective measures may be necessary for comprehensive safety.

When selecting cut resistant fabric, factors such as the level of cut protection required, durability, comfort, flexibility, and compatibility with other protective equipment should be taken into account to ensure optimal performance in the intended application.

Generally, thicker cut resistant fabric tends to offer higher levels of cut protection. However, the trade-off is often reduced flexibility and dexterity. It is important to strike a balance between thickness and flexibility based on the specific requirements of the application and the desired level of protection.