Tel: 0086769-23187408

Email: [email protected]

Tel: 0086769-23187408

Email: [email protected]

By incorporating cut-resistant fabric into gloves, aprons, and other garments, workers in the food processing industry can perform their tasks with confidence, knowing they are protected from potential accidents and helping maintain the integrity of the food products they handle.

NIZE specializes in manufacturing cut resistant fabric that performs well under repeated mechanical stress. Our stable supply chain and stringent quality control make us a trusted partner for protective fabric sourcing.

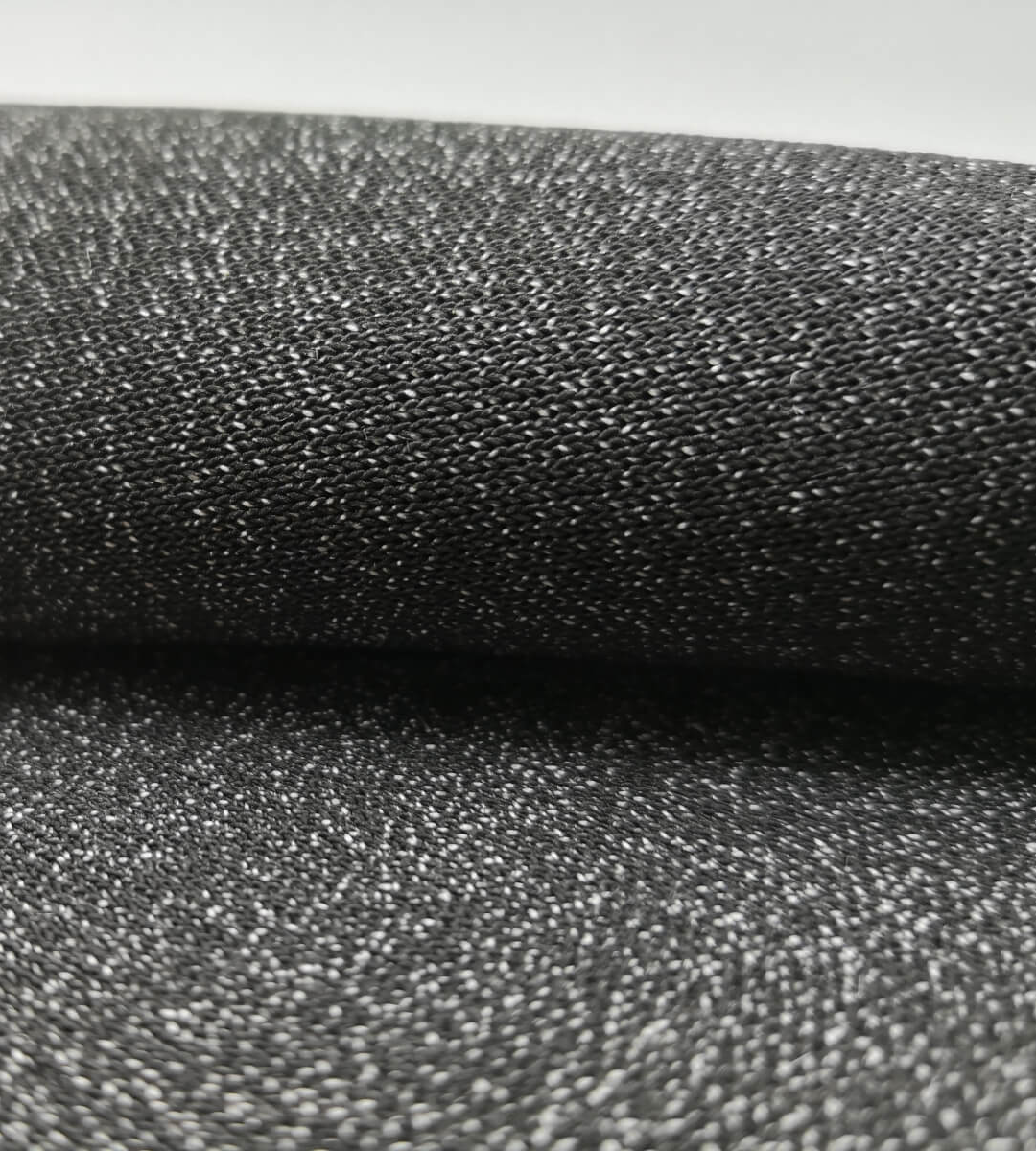

NIZE delivers cut resistant fabric with superior tensile strength and consistent performance. This textile supports high-stress applications, allowing B2B buyers to maintain strict safety and durability standards across product lines.

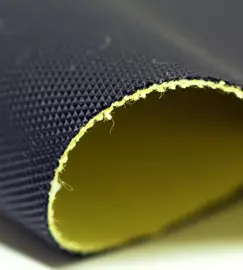

Innovative weaving or knitting technologies combine tough fibers to ensure that tear strength in cut-resistant fabric is achieved. This feature of the fabric makes it less prone to tearing, thus keeping its structure intact even under extreme pressure and friction.

Tear resistance is very important in areas like construction, manufacturing and carpentry where workers are likely to come into contact with sharp tools as well as rough surfaces or abrasive substances. Cut-resistant materials prevent lacerations resulting from splitting or cutting which could otherwise endanger the lives of operators.

Cut-resistant fabrics also improve the safety of workers and prolong their useful life. Over time, it maintains integrity by not getting torn hence businesses do not have to replace them frequently and this saves money.

Therefore, rip-proof nature of cut-resistant fabrics enhances safety measures for workers as well as durability and confidence. Companies’ use of these materials in their safety guidelines would be a significant step in helping them avoid tears on their employees consequently reducing risks of injuries at workplaces.

NIZE supports industrial buyers with large-volume orders of cut resistant fabric. Our efficient production systems ensure timely delivery and stable quality, even for complex specifications or tight deadlines.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

Cut resistant fabric provides reliable protection against cuts, reduces the risk of injuries, enhances worker safety, and improves overall productivity in high-risk work environments.

Yes, cut resistant fabric can be tailored to meet specific requirements, including different cut resistance levels, thicknesses, and garment designs to suit various industry needs.

While cut resistant fabric provides excellent protection against cuts, it may have limited resistance to other hazards like punctures, chemicals, or heat. Additional protective measures may be necessary for comprehensive safety.

When selecting cut resistant fabric, factors such as the level of cut protection required, durability, comfort, flexibility, and compatibility with other protective equipment should be taken into account to ensure optimal performance in the intended application.

Generally, thicker cut resistant fabric tends to offer higher levels of cut protection. However, the trade-off is often reduced flexibility and dexterity. It is important to strike a balance between thickness and flexibility based on the specific requirements of the application and the desired level of protection.