Tel: 0086769-23187408

Email: [email protected]

Tel: 0086769-23187408

Email: [email protected]

Anti-saw fabric is engineered to be easy to move and hard-wearing, and its lightweight properties and breathability help reduce fatigue during extended use, making it ideal for those who need both protection and mobility.

NIZE specializes in developing high-performance anti-saw fabric tailored for industrial-grade safety needs. The fabric resists cutting forces from saw blades, offering advanced protection in demanding environments. NIZE supports OEM customization and large-volume supply, ideal for protective gear manufacturers and B2B procurement teams.

With a solid reputation in technical fabric manufacturing, NIZE has become a preferred supplier for B2B safety product providers. We combine strong production capabilities with responsive customer support, ensuring timely fulfillment and material compliance with protective standards.

NIZE collaborates with B2B partners to integrate anti-saw fabric into their protective equipment lines. Whether you're developing gloves, vests, or tool covers, our materials meet the high standards needed for end-user safety and product durability.

A certain extent of protection may be available with traditional work clothes, but it goes further with anti-saw fabric. This ensures a higher level of safety that enables workers to carry out their duties without compromising on their health.

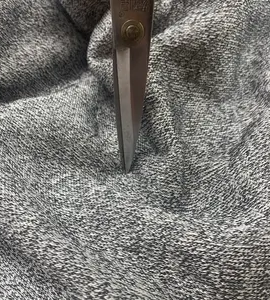

One of the key features in saw resistant fabric is its unmatched resistance to saw blades and cutting tools. By tightly woven fibers and strengthened structure, the fabric acts as a strong barrier thus reducing substantially the danger of accidental contact injury.

In addition to providing protection, anti-saw fabrics are also designed for comfort and durability. It has light weight, breathability and malleability thereby making movement easy and maintaining well-being throughout the day. Its robust construction guarantees longevity and can withstand tough working conditions.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

Anti-saw fabric is a specially designed textile that provides protection against sawing and cutting hazards and resists penetration by saw blades and cutting tools, reducing the risk of injury in high-risk environments.

Anti-saw fabric uses tightly woven fibers and reinforcements to create a strong barrier. This barrier impedes the advancement of saw blades and cutting tools, preventing them from penetrating fabric and reducing the potential for serious injury.

Anti-saw fabrics can be used in a range of industries where sawing and cutting hazards need to be protected. It is commonly used in industrial settings, construction sites, law enforcement and military applications, and in personal protective equipment (PPE) manufacturing.

The main advantage of anti-saw fabric is its ability to provide reliable protection against sawing and cutting hazards. It reduces the risk of injury and ensures a safer working environment. Additionally, anti-saw fabric is durable, lightweight and breathable, providing comfort and freedom of movement to the wearer.

The performance of anti-saw fabrics is typically evaluated through standardized testing methods. These tests include subjecting the fabric to saw blades, cutting tools or simulated cutting forces to assess its resistance and protective capabilities.