Tel: 0086769-23187408

Email: [email protected]

Tel: 0086769-23187408

Email: [email protected]

The waterproof fabric provides good moisture protection, allowing outdoor enthusiasts to stay dry and comfortable in all weather conditions. Whether it's a waterproof jacket to keep out the rain, a tent to withstand a downpour, the application benefits of waterproof fabrics ensure durability, reliability and enhanced performance.

A number of factors can make car interiors wet or moist. Such factors include rain, spills, and condensation. In order to meet this challenge, waterproof fabrics are an essential problem solver that ensures reliable moisture protection and enhances comfort for the driver as well as passengers.

This is achieved through the use of water resistant fabrics on seats upholstery, door panels and headliners which form a protective barrier against penetration of interior components by spillage or rainwater. This characteristic helps keep your car’s interior neat and clean thus increasing its life expectancy by reducing the likelihood of molds developing and bad smell.

Waterproof fabrics remain visually appealing with their original texture even when exposed to wetness thus maintaining attractive interiors. A wide range of hues, designs and finishes allow automakers to create stylish customized designs that match their corporate image as well as consumer preferences.

Additionally, water resistant fabrics offer more comfortable car interiors than those which lack such qualities while also serving aesthetic purposes. Due to their breathability characteristics, these textiles often allow air exchange in vehicles thereby avoiding accumulation of moisture inside them. This attribute aids in minimizing discomfort during driving under rainy conditions with wet fabric on one's body hence providing a soothing experience for drivers. Moreover, many times they are easy to wash since these materials are frequently used; it becomes very simple for vehicle owners to maintain sanitary conditions in their cars’ inner space.

For clients seeking customized fabric solutions, NIZE delivers waterproof fabric with a variety of finishes and backing options. We work closely with buyers to meet design and durability requirements.

Weight matters in portable gear. NIZE offers lightweight waterproof fabric without compromising on strength or water resistance, allowing flexibility in design for clothing, bags, and outdoor equipment.

NIZE helps businesses enhance product reliability using our high-performance waterproof fabric. Its layered construction and consistent coating quality support superior resistance to water, oils, and environmental damage.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

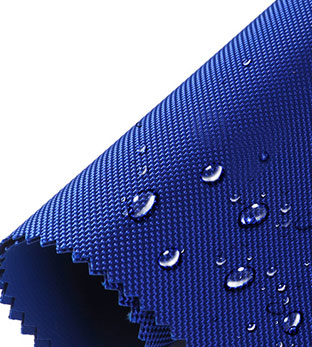

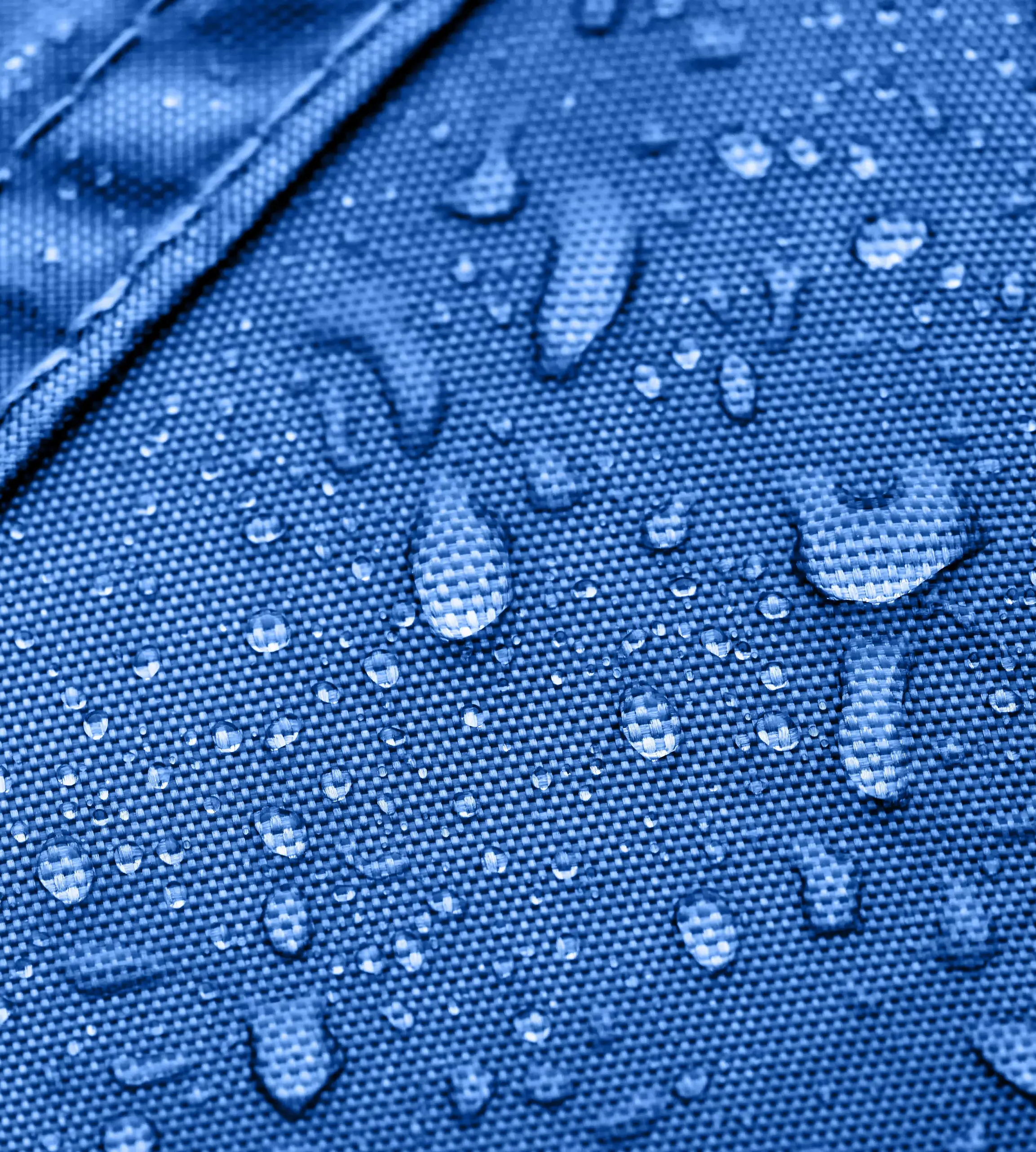

Waterproof fabrics are designed with special coatings or membranes that create a barrier against water penetration. These coatings repel water while allowing vapor to escape, ensuring breathability and preventing moisture buildup.

Waterproof fabric undergoes rigorous testing and quality control measures to ensure its durability and longevity. Additionally, manufacturers often provide guidelines for proper care and maintenance, such as regular washing and reapplying waterproof treatments if necessary, to maintain its effectiveness.

Waterproof fabrics maintain breathability through the use of advanced technologies such as microporous membranes or coatings. These technologies allow moisture vapor to escape from the fabric while preventing liquid water from entering.

Yes, efforts are being made to produce waterproof fabrics using sustainable materials and manufacturing processes. Some waterproof fabrics can be recycled, reducing their environmental impact and promoting a more circular and eco-friendly approach to textile production.

Waterproof fabrics are typically made from synthetic materials such as polyurethane (PU) or silicone-based coatings. These coatings are applied to the fabric surface using various techniques such as spraying, lamination, or dipping. Other materials that are often used in waterproof fabrics include Gore-Tex,eVent, and different types of nylon or polyester.