Tel: 0086769-23187408

Email: [email protected]

Tel: 0086769-23187408

Email: [email protected]

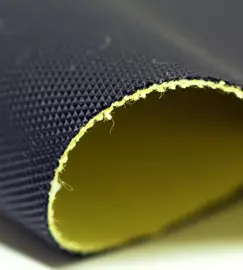

Cut-resistant fabrics demonstrate their versatility in the demanding automotive industry, where workers are exposed to potential hazards from sharp edges, metal fragments and other sharp objects. Cut-resistant fabrics are engineered to provide reliable Protects against cuts, cuts and punctures, making it a safe haven for auto workers.

NIZE specializes in manufacturing cut resistant fabric that performs well under repeated mechanical stress. Our stable supply chain and stringent quality control make us a trusted partner for protective fabric sourcing.

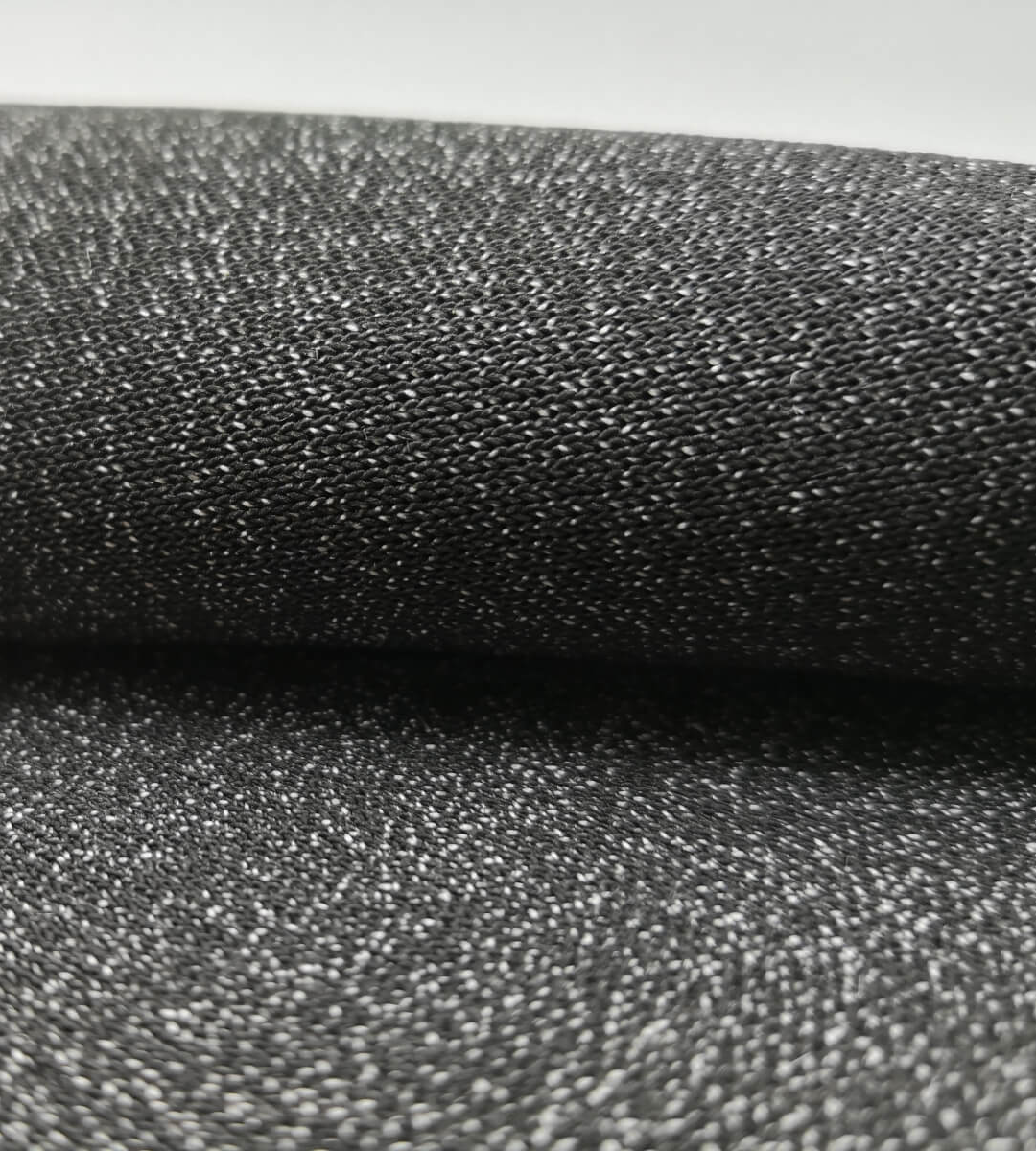

We understand the varied needs of B2B clients. NIZE provides customized cut resistant fabric options, including different weaves, thicknesses, and composite structures to suit unique application requirements.

In all fields cut- proof fabrics have changed the way safety is played, providing strong protection against cuts and stabs. These new materials instead of being used for traditional purposes only are now placed in working areas where accidents of different types occur.

In addition, these salvos reduce injuries in food plants by making gloves and clothes from the same compounds that prevent sharp knives and blenders from cutting hands and limbs. Gloves and garments do not only drive away dangerous substances but also give nice touches which are necessary for a user’s safety without affecting his/her work efficiency while handling tools or goods.

The manufacturing industry is also another domain where the use of cut-resistant fabrics is widespread. Employees in these sectors encounter various premium quality tools like those found in metal fabrication, glass processing or car assembly. A wear resistant to any cut etc resembles like an extra level of inherent defense against scratches, lacerations possible during manufacture.

Basically versatile applications of cut resistant fabrics mark out their adaptability abilities which improve individual security in diverse industries. They show how important it is to have innovative textiles on everyday basis to industrial practitioners’ health at work.

NIZE delivers cut resistant fabric with superior tensile strength and consistent performance. This textile supports high-stress applications, allowing B2B buyers to maintain strict safety and durability standards across product lines.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

Cut resistant fabric provides reliable protection against cuts, reduces the risk of injuries, enhances worker safety, and improves overall productivity in high-risk work environments.

Yes, cut resistant fabric can be tailored to meet specific requirements, including different cut resistance levels, thicknesses, and garment designs to suit various industry needs.

While cut resistant fabric provides excellent protection against cuts, it may have limited resistance to other hazards like punctures, chemicals, or heat. Additional protective measures may be necessary for comprehensive safety.

When selecting cut resistant fabric, factors such as the level of cut protection required, durability, comfort, flexibility, and compatibility with other protective equipment should be taken into account to ensure optimal performance in the intended application.

Generally, thicker cut resistant fabric tends to offer higher levels of cut protection. However, the trade-off is often reduced flexibility and dexterity. It is important to strike a balance between thickness and flexibility based on the specific requirements of the application and the desired level of protection.