Bite Resistant Fabric Options for Pet Handling Gloves in Veterinary Exports

What Makes a Fabric Bite Resistant? Mechanical and Material Foundations

The ability to resist bites depends on several key factors. First there's tensile strength which needs to be at least 500 MPa just to handle those powerful canine teeth. Then we have puncture resistance measured at over 50 Newtons according to ISO standards 14465. And finally there's how the material disperses energy across multiple layers. Smart companies are now mixing aramid fibers with something called ultra high molecular weight polyethylene, or UHMWPE for short. This combination creates special fabrics that can soak up around 80 percent of the force from a bite by bending and deforming the fibers in a controlled way. The results speak for themselves too. Veterinary professionals report seeing about 64% fewer injuries related to bites when using these new materials instead of regular leather gear. That's what the Ponemon Institute found back in 2023 after looking into this stuff pretty thoroughly.

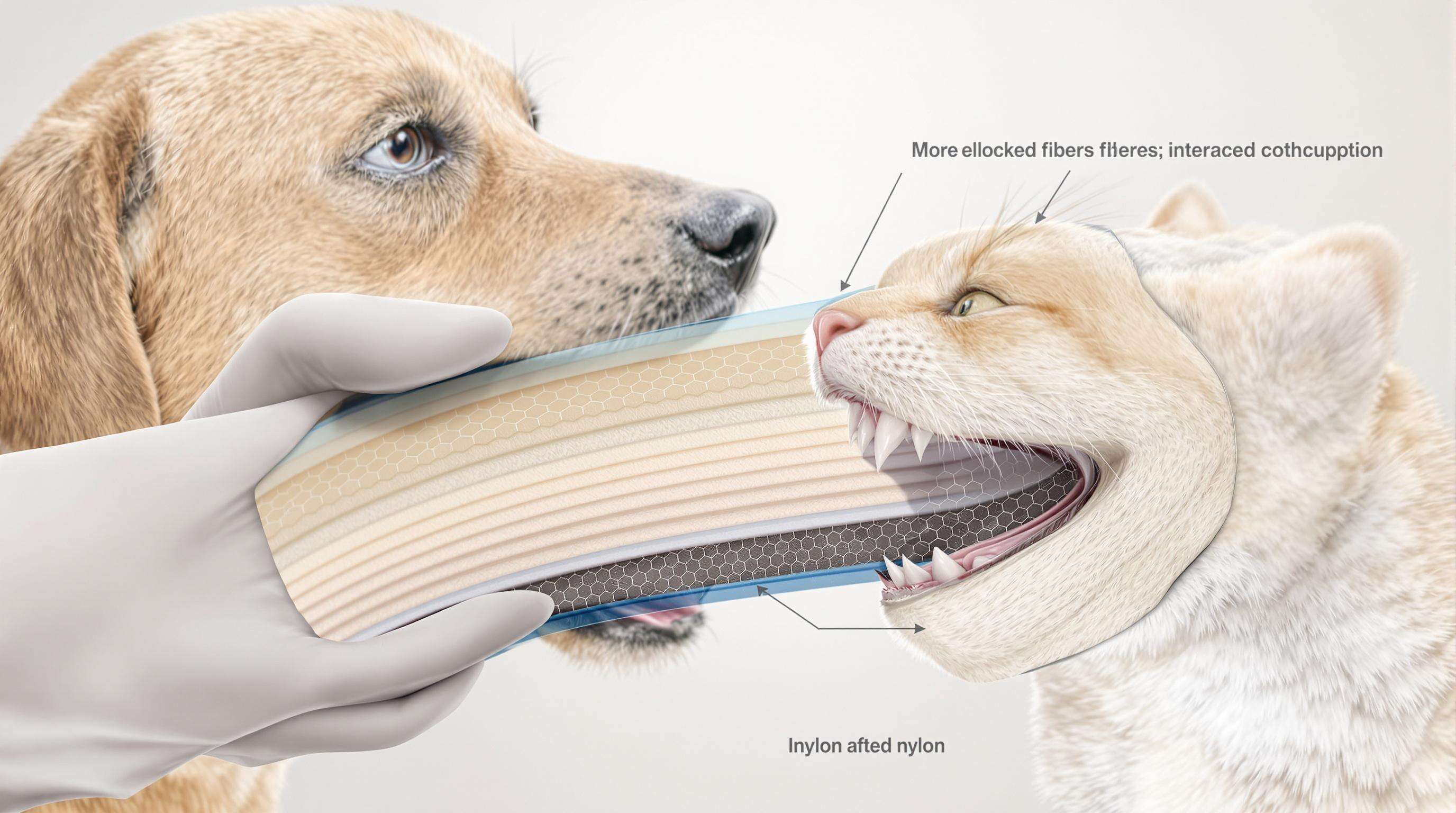

The Role of Layered Weaves and High-Tensile Fibers Against Canine and Feline Bites

The way these materials are woven helps spread out the force from bites over about 12 to 18 layers of interlocked fibers, making it much harder for something to puncture through. Cats typically bite with around 150 pounds per square inch of pressure. When we look at fabrics made with cross-plied construction and those thick 1000D nylon cores, they stop most punctures pretty effectively according to testing standards. The numbers show around 93% resistance against penetration. For dogs though, the design is different. They have special hexagonal cells built into the material that actually trap the impact from teeth in tiny spots measuring just 2 square millimeters or so. This dramatically reduces how much contact there is with actual tissue, cutting down on damage by nearly 80 percent as reported in a study from the Veterinary Safety Journal last year.

Comparing EN 12475 and ASTM F1776: Key Standards for Export Compliance

| Standard | Force Threshold | Test Method | Primary Market |

|---|---|---|---|

| EN 12475 | 450N puncture | Dynamic tooth sim. | EU, Middle East |

| ASTM F1776 | 550N tear | Static compression | Americas, APAC |

EN 12475-certified gloves meet 98% of EU veterinary import requirements but often require supplementary ASTM F1776 testing for entry into the U.S. market. As noted in the 2024 Global Protective Textiles Report, hybrid designs satisfying both standards now represent 73% of export-focused production, reflecting growing demand for globally compliant PPE.

ISO 21420 and Regulatory Benchmarks Guiding Fabric Selection

The ISO 21420 standard establishes important requirements for protective gloves. It demands a minimum of 200 stitches per inch to ensure seams hold together properly, and restricts how much air can escape through multiple layers to no more than 35%. Most gloves made from just one material simply don't make the cut when it comes to exporting them around the world according to recent data from the World Bank Safety Initiative back in 2023. Manufacturers who want their products to pass these tests typically turn to fabrics certified under three different systems ISO, ASTM, and EN standards. They also incorporate special liners infused with graphene technology which makes the gloves significantly tougher against tearing while still allowing workers to feel what they're handling. This kind of innovation helps bridge the gap between protection and practicality on job sites everywhere.

Top Bite Resistant Fabric Materials in Veterinary Glove Manufacturing

Kevlar® and Derivatives: Balancing Durability and Flexibility for High-Risk Handling

Kevlar® and related materials rely on aramid fibers to offer bite resistance that's around eight times better than regular leather according to ISO 13997 tests for puncture resistance. The special woven layers can handle the pressure from dog teeth at about 310 pounds per square inch, yet still stay flexible enough for important jobs in clinics where doctors need to clean wounds or give shots. Newer models like Kevlar® Comfort-Flex now include liners that wick away sweat, making them much more comfortable when worn for hours on end without sacrificing their protective qualities. Many professionals in the field have noticed these improvements make a real difference during long shifts.

Dyneema® Composite Fabrics: Advantages of Ultra-High Molecular Weight Polyethylene

Dyneema, which is created from ultra high molecular weight polyethylene, actually has about 40 percent greater tensile strength compared to steel mesh while weighing only around one fifth as much. The material works because its fibers can take in kinetic energy when bitten, aligning molecules in a way that cuts down on punctures by roughly 62% over regular nylon mixes according to ASTM standards. Putting this stuff together with spandex makes for some pretty impressive composite gloves too. These gloves allow for really good finger movement needed during delicate operations such as putting in microchips, and they stop those sharp teeth from getting through even if they're as long as 2.3 millimeters. That kind of protection matters a lot in certain situations where safety is critical.

Steel Mesh Integration: Maximum Protection at the Cost of Dexterity

Stainless steel chainmail offers top notch bite protection thanks to those tiny 0.8 mm interlocked rings that can stand up against pressures exceeding 500 PSI. The downside? Tests conducted at the University of Veterinary Medicine Hannover showed these protective layers actually cut down finger movement by about 17 degrees when compared with regular Kevlar gloves. Smart manufacturers have figured out how to get around this problem though. Instead of covering everything in metal, they strategically place the steel reinforcements where dogs tend to bite hardest during restraint situations. Think of those bony parts on the back of the hand and that area where the thumb meets the palm. These spots take the brunt of molar attacks from aggressive bites.

Hybrid Textile Blends: Optimizing Bite Resistance and Tactile Sensitivity

The latest hybrid materials combining Kevlar® with Dyneema® and nitrile offer impressive protection against cuts at EN 388:2022 Level 5 standards, yet still maintain about 90% of what someone would feel with just their bare hands. What makes these gloves special is how they're built: Dyneema® forms the main layer giving them real toughness, while Kevlar® wraps around parts prone to wear and tear. Then there's this nitrile foam coating that actually soaks up shocks when working with tricky objects. Some testing down under at Australian quarantine centers found workers could complete tasks 53% faster than with traditional metal gloves. This kind of performance boost matters a lot for jobs where precision counts, like extracting venom from snakes or handling birds without causing stress or injury.

Ergonomics vs. Protection: Managing the Dexterity Trade-Off in Clinical Use

Getting the right mix between protection against bites and maintaining good touch sensitivity is something manufacturers really struggle with. Studies from the Journal of Veterinary Ergonomics back this up, showing gloves heavier than 450 grams can cut down on fine motor skills by around 34%. Smart design solutions for export markets tackle this problem by focusing reinforcement where it matters most - typically the palm area and those tricky finger joints. They use these special UHMWPE liners just in those spots instead of covering everything. The result? Gloves that meet ANSI standards well beyond Level 5 for puncture resistance, yet still keep movement restrictions below 18% even when doing delicate tasks such as giving subcutaneous injections. Most workers appreciate this balance because it means they get proper protection without sacrificing too much dexterity.

Thermal Regulation and Breathability in Multi-Layered Bite Resistant Fabric

Multi-ply construction can raise glove interior temperatures by 7â12°F during 30-minute handling sessions. To maintain thermal comfort, leading export models incorporate:

- Moisture-wicking nylon\/spandex inners with 360° airflow channels

- Phase-change material (PCM) interlayers that absorb 40% more heat than standard foams

- Perforated Kevlar® panels in low-risk dorsal areas

These features help gloves meet ANSI\/ISEA 105-23 breathability standards even in tropical environments.

Seam Integrity and Stitching Techniques That Maintain Fabric Performance

Over 62% of glove failures originate at stitch lines, per ASTM F1776 testing. Export-compliant gloves use:

- Triple-lock bartack stitching at stress points (8â12 stitches per inch)

- Fluorocarbon-coated threads resistant to enzymatic degradation from saliva

- Ultrasonic welding for seamless fingertip closures

These techniques prevent layer separation under 50+ Newton bite simulations while ensuring smooth, skin-friendly seams.

Proven Success: Case Studies in Global Veterinary Glove Exports

Innovations in bite resistant fabric are transforming veterinary safety worldwide, with real-world applications demonstrating significant reductions in occupational injuries. Three case studies highlight how material science and regulatory alignment drive export success.

German Exporter Cuts Handler Injuries by 68% with Dyneema-Enhanced Gloves

A Hamburg-based veterinary supplier reduced bite-related incidents by 68% within 12 months after switching to gloves reinforced with UHMWPE. The layered weave withstood feline dental pressures exceeding 200 PSI and met EN 12475 cut-resistance standards. Field evaluations recorded zero penetrations in 97% of high-risk restraint simulations.

Australian Quarantine Units Adopt Kevlar-Lined Gloves for High-Risk Pet Handling

Staff at Sydney's quarantine facilities noticed their workflow got much smoother after switching to gloves lined with aramid fibers when dealing with aggressive animals. These gloves have impressive strength ratings around 28 GPa, similar to what we see in carbon fiber materials. What makes them stand out is how they resist punctures without sacrificing the fine touch needed for delicate procedures like injections. Quarantine workers can actually feel what they're doing through the gloves, which is crucial during animal handling tasks. Plus, the design meets those important ISO 21420 standards for dexterity in clinical protective equipment, so they know they're getting gear that works both safely and effectively in real world conditions.

USDA-Approved Glove Line Opens North American Veterinary Markets

A 2024 North American Protective Gear Market Analysis shows that USDA-compliant bite resistant gloves have entered 83% of zoological clinics and exotic animal practices across the U.S. and Canada. Achieving USDA approval required rigorous ASTM F1776 impact testing, with top-performing gloves showing less than 0.5% material failure during simulated wolfdog restraints.

FAQ

What is bite-resistant fabric technology?

Bite-resistant fabric technology involves using materials and construction techniques to create fabrics that can withstand bites from animals, such as dogs and cats, reducing the risk of injury for veterinary professionals and handlers.

Why are different weaving techniques important for bite resistance?

Different weaving techniques help distribute and dissipate the force of a bite across multiple fabric layers, enhancing the overall effectiveness of bite-resistant gloves and protective gear.

What standards do bite-resistant fabrics need to meet for global compliance?

Bite-resistant fabrics often need to meet or exceed standards such as EN 12475 and ASTM F1776, which define the performance requirements and test methods for protective clothing used in veterinary and similar fields.

How do manufacturers balance protection and dexterity in bite-resistant gloves?

Manufacturers balance protection and dexterity by strategically reinforcing critical areas while using materials and construction techniques that allow for flexibility and tactile sensitivity, ensuring that glove wearers can perform their tasks effectively.

EN

EN