Archery Target Cloth That Stops Arrows Quietly and Lasts Longer

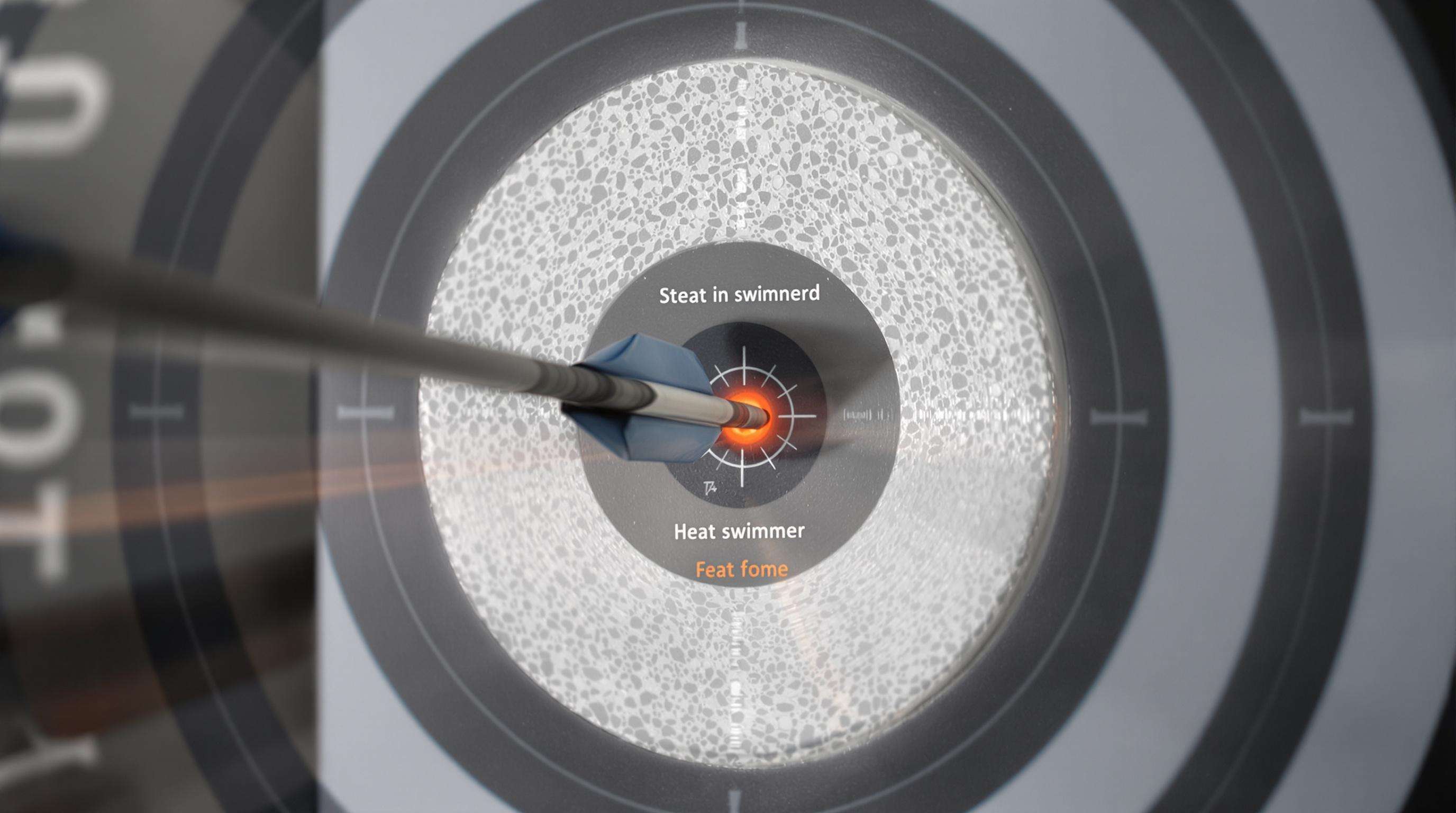

How Archery Target Cloth Stops High-Velocity Arrows Quietly

Kinetic Energy Absorption in High-Velocity Arrow Impacts

The latest archery targets are designed to absorb arrow impact by compressing special materials that soak up energy. Inside these targets, layers of closed cell foam get squashed when hit, turning around 92 percent of what an arrow brings into heat within just under a quarter second according to research published last year in the International Journal of Sports Engineering. What this means is that arrows stop properly without going all the way through the target, and works reliably whether shooting at speeds around 250 feet per second or faster up to about 500 fps. The gradual slowdown makes these modern targets much safer and more durable than older models.

Role of Layered Foam in Reducing Noise and Controlling Penetration

Foam stacks made from multiple densities cut down on noise levels around 50 to maybe even 60 percent when compared with those old fashioned straw targets. They do this because they spread out the force of impacts across between six and twelve different layers of material. The special viscoelastic polymers used help absorb those annoying high frequency vibrations that tend to carry through structures. Plus there's a surface layer designed specifically for fletching contact points which helps prevent any major damage to surrounding structures. According to tests published in the Acoustic Materials Report last year, stacking fourteen layers of polyethylene foam brings peak noise levels down to just 68 decibels. That's actually quieter than what most people talk at during regular conversations.

Balancing Quiet Arrow Capture with Structural Integrity

Manufacturers achieve optimal balance between durability and noise reduction through advanced material engineering:

| Property | Performance Threshold | Testing Standard |

|---|---|---|

| Cycles to failure | 300+ shots | ASTM F2212-18 |

| Broadhead penetration | <5" depth | ATA Safety Protocol |

| Sound emission | <72 dB | ISO 17201-3 Certification |

Cross-linked polymer formulations exhibit less than 3% permanent deformation after 100 shots, ensuring long-term integrity and easy arrow removal. Hybrid composites incorporating 20–40% recycled rubber particles offer 35% greater tear resistance than pure foam cores without sacrificing acoustic performance.

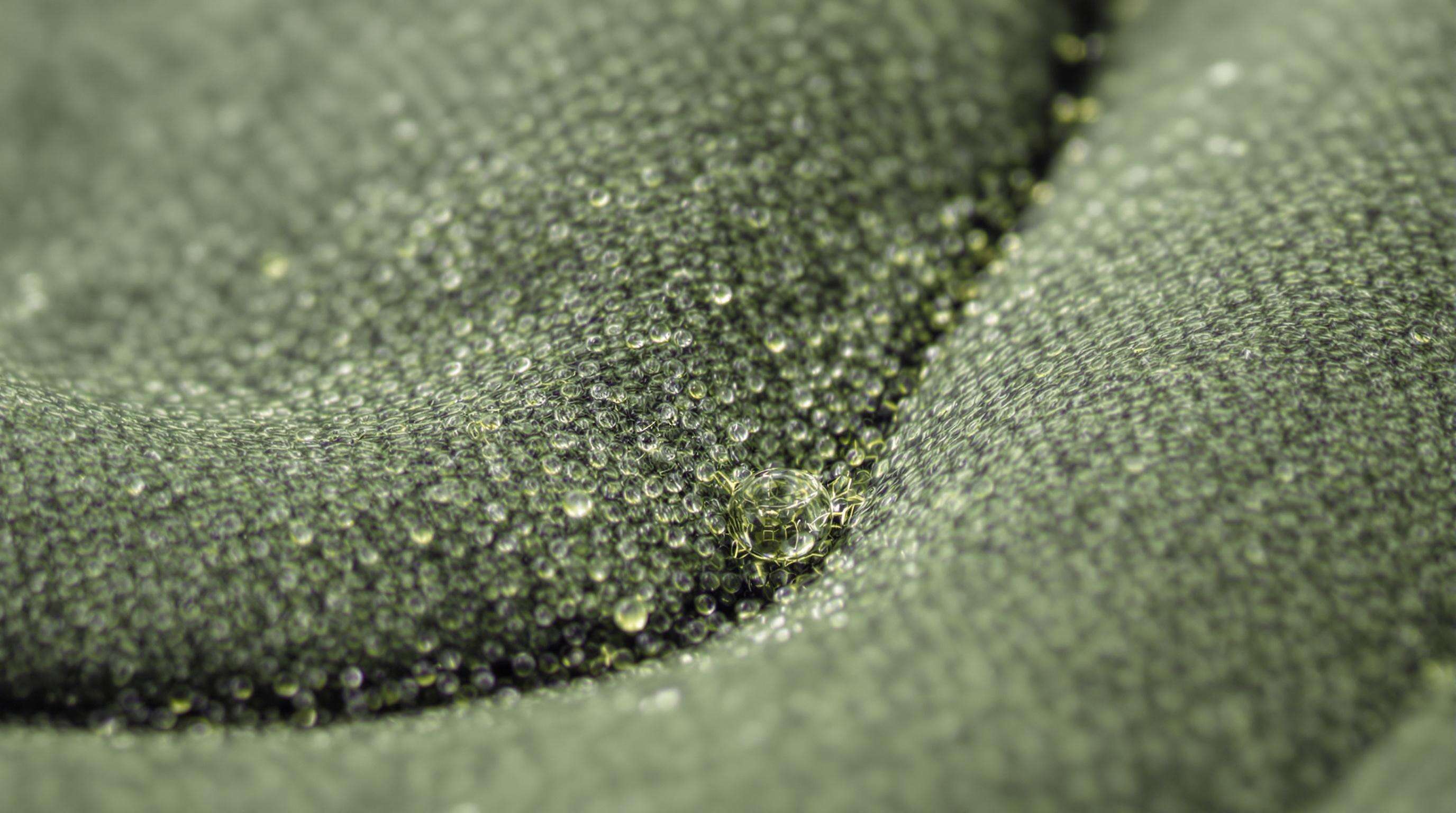

Self-Healing Technology for Extended Archery Target Longevity

How Self-Healing Foam Repairs Arrow Holes and Prevents Tear Propagation

The latest archery targets are now made with special fabric that mimics how living things heal themselves. When an arrow goes through it, tiny capsules inside release healing fluids under pressure right where the damage happens. These fluids create a flexible seal almost instantly. According to a study published last year in Materials Science Journal, this repair stuff manages to get back to about 83% of what the foam was originally like. That means the targets keep their strength and ability to stop arrows even after being hit many times over. Archers can shoot at them repeatedly without worrying about the target falling apart or losing effectiveness between shots.

Long-Term Performance Benefits in High-Use 3D Archery Ranges

At commercial shooting ranges that see over 500 rounds fired each day, these self healing targets actually hold up around eight times better than regular foam targets. The secret lies in their closed cell construction which keeps water out, plus special additives that stop tears from spreading much beyond about 1.5mm around where bullets hit them according to some tests done by Outdoor Gear Lab back in 2023. What does this mean practically? Well maintenance staff don't have to replace them as often anymore. Instead of needing fresh installations every three months or so, many facilities now find they can wait almost two full years between replacements depending on local weather conditions.

Cost vs. Value: High Initial Investment vs. Reduced Replacement Frequency

Although self-healing archery target cloth carries a 40% higher upfront cost, its total cost of ownership becomes favorable within 18 months. A 2025 market analysis indicates commercial ranges save $12,000 annually per target lane through reduced maintenance and disposal expenses. For home users, the technology triples usable shot capacity before rotation is required.

Weather-Resistant Construction for Durable Outdoor Archery Targets

All-Weather Materials: UV-Resistant Outer Layers and Moisture-Resistant Cores

Today's archery target cloths have UV resistant outer layers paired with moisture resistant cores so they can stand up to tough outdoor conditions. Manufacturers treat the outer fabric with special UV inhibitors which cut down on sun damage quite a bit actually around 80% according to those accelerated weathering tests they run in labs. Underneath all that protection lies either closed cell foam or compressed synthetic fibers creating a barrier against water absorption. This makes modern targets much better than old fashioned ones that basically fall apart once they get soaked during rainstorms or morning dew.

Extending Lifespan with Environmental Protection Features

Manufacturers now build hydrophobic coatings and antimicrobial treatments right into the fabric of target cloths during production. This approach stops mold from forming when humidity levels rise and keeps the material intact even through repeated freezing and thawing in cold climates. Real world testing has demonstrated impressive results too. After sitting outside for a full year, these protected targets maintain around 90% of their initial effectiveness at stopping projectiles. That's quite a contrast from standard weather resistant versions which typically drop down to about half their original performance level under similar conditions.

Comparison: Traditional Straw Targets vs. Modern Synthetic Archery Target Cloth

| Feature | Straw Targets | Synthetic Target Cloth |

|---|---|---|

| Average Lifespan | 3–6 months | 2–5 years |

| Water Resistance | Absorbs 40% weight | Repels 98% moisture |

| UV Degradation | Significant fading | <5% color loss annually |

| Maintenance Cost | $120/year | $20/year |

Synthetic designs eliminate straw’s vulnerabilities to rot and pests while delivering consistent arrow-stopping performance in all weather conditions.

Material Innovations Driving Performance in Modern Archery Target Cloth

From Natural Fibers to Advanced Composites: Evolution of Target Materials

The materials used for archery targets have come a long way since the days of simple burlap sacks filled with straw. Back in the old days, those natural fiber targets would break down pretty fast, often losing around 40% of their ability to stop arrows after just half a year according to some research from the Outdoor Sports Institute back in 2023. These days we see much better options on the market. Manufacturers now create layered fabric targets using stuff like high density polyethylene mixed with aramid fibers. These modern targets can absorb about 92% of an arrow's energy and most last well past 10 thousand shots before showing any real signs of wear. Shooters appreciate this because it means fewer replacements and more consistent performance during practice sessions.

Tested Performance: Penetration Resistance of Top Archery Target Materials

Third-party evaluations highlight significant performance differences among materials:

| Material Type | Penetration Depth (70# Compound Bow) | Noise Level (dB) | Shot Cycles to Failure |

|---|---|---|---|

| Traditional Jute | 18.2" | 84 | 300–500 |

| Multi-Layer Polypropylene | 9.8" | 72 | 2,000+ |

| Carbon-Infused HDPE | 6.3" | 68 | 5,000+ |

Composites with directional fiber alignment demonstrate 63% higher tear resistance than homogeneous foams under ASTM F2216 testing standards.

Best Practices for Maximizing Durability in High-Traffic Shooting Environments

- Rotate impact zones weekly to distribute wear evenly

- Use reinforced backstop netting (minimum 400gsm) to reduce stress on the primary target

- Apply silicone-based protectants quarterly to preserve water resistance

- Store vertically in low-humidity environments between uses

Leading manufacturers now embed UV inhibitors directly into fabric coatings, extending outdoor service life by 3–4 times compared to untreated materials. Moisture-wicking core layers prevent internal degradation, a critical advancement for field targets exposed to seasonal weather changes.

FAQ

What materials are used in modern archery targets?

Modern archery targets use advanced composites like high-density polyethylene mixed with aramid fibers, enhancing their energy absorption capacity and durability.

How does self-healing technology in targets work?

Self-healing technology uses tiny capsules within the target that release healing fluids under pressure, sealing arrow holes almost instantly and restoring target integrity.

What is the lifespan of synthetic archery target cloth versus traditional straw targets?

Synthetic archery target cloth has an average lifespan of 2-5 years, significantly outlasting traditional straw targets which last only 3-6 months.

EN

EN