Industrial Applications of Bite Resistant Fabric in High - Risk Work Environments

Material Engineering Breakthroughs in Bite Resistant Fabric

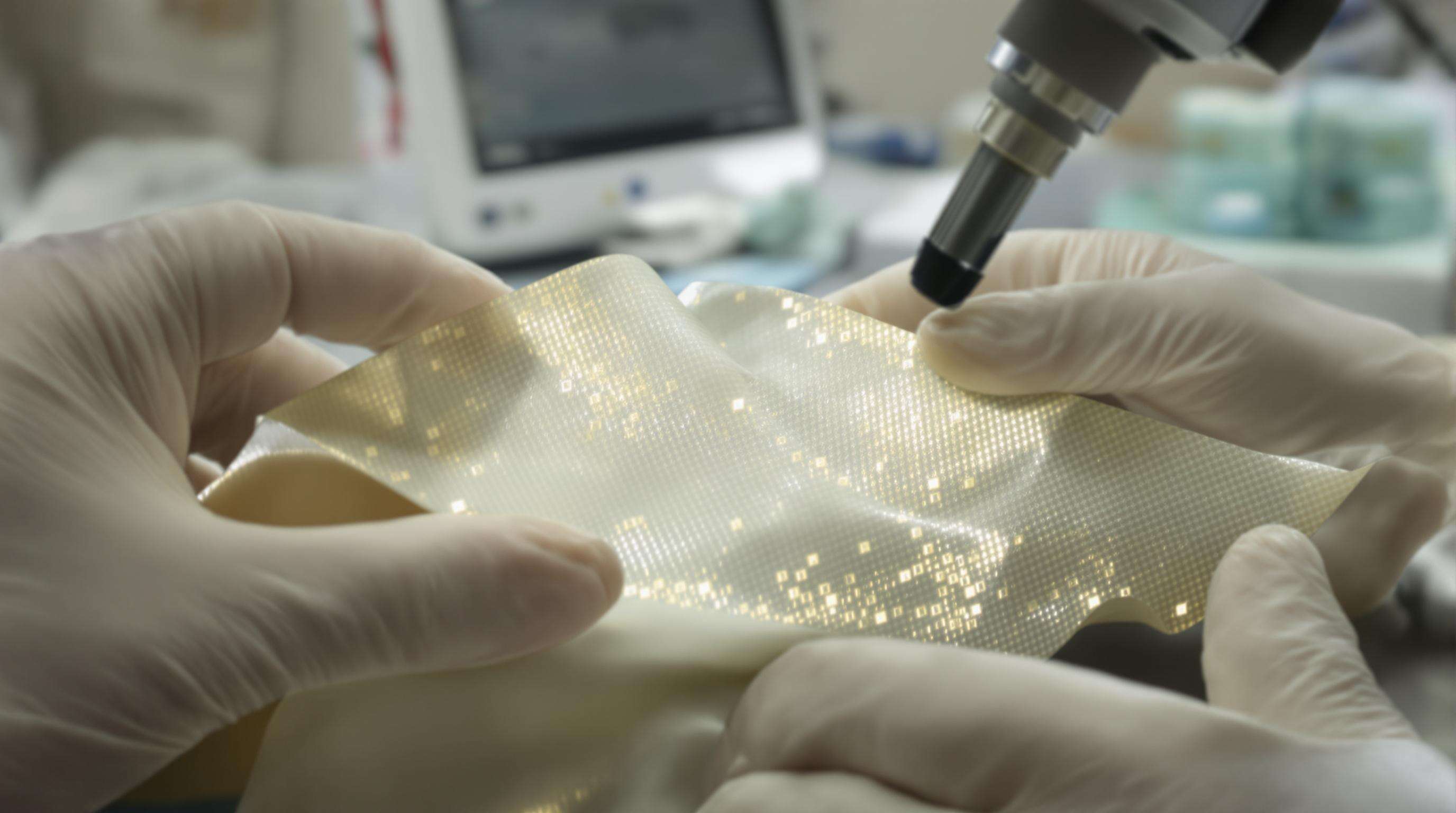

Advances in material engineering have transformed bite resistant fabrics to improve protection in high-risk industries. State of the art polymer chemistry and manufacturing makes these long lasting, flexible and provides puncture resistant. The developments center on molecular orientation and fiber-to-fiber bonding processes, which disperse the force of impact. Top testing facilities have reported over 60% more tear resistance than traditional materials in standard "bite simulation" tests, and, through heat-molding at home, made-to-measure fitting is quick and easy.Ultra LightStockists of Dentec Safety Comfort Plus Face Masks"Comfort Plus" face masks address the short comings of all other face masks: "one size does not fit all"!Key Features:500% more tear resistant than other sports-related protective face masksSoft, strong and silent - does not rub when wet or crumple as easily as other face masksPrevents Damage: Quick and easy to heat-mold for customised "fit"Completely hygienic - will not sustain bites or tearsExcellent visual clarity - does not obstruct visionDoes not require repositioning or adjustment in playingAdjustable and comes in 3 sizes - Junior/Small, Regular and LargeSizes Junior/Small Ideal For:Junvenile justice workersExotic animal handlersAnimal control officersZoo keepersCircus workersLaw enforcementpersons in military or law enforcement who may prefer a negative pressure respirator.Prevailed by shape, not size.

Case Study: Synthetic Fiber Blends Enhancing Durability

The hybridization with synthetic fibers has increased bite fabric strength dramatically. Engineers have also designed composite fabrics using ultra-high-molecular-weight polyethylene (UHMWPE) and liquid-crystal polymers, and interlocking meshes that transfer biting force. These fabrics are multlayered and reach Level 5 cut according to ISO 13997 standards, and yet retain their flexibility. They were found to withstand greater than 300 bite cycles without failure, indicating a 170% improvement over direct materials. Such technology is especially important in the livestock industry, where repeated abrasive wearing is present, necessitating highly durable fabric.

Compliance Mandates: Bite Resistant Fabric in Safety Regulations

Regulatory bodies worldwide now mandate bite-resistant fabric in occupational settings involving animal exposure. Compliance requirements are driven by documented injury reductions exceeding 45% when certified protective gear is used. OSHA, EU-OSHA, and similar agencies reference specific performance thresholds for penetration resistance in updated safety codes.

The new EN 14126 now certifies this protection against biological hazards, too, and therefore includes tear resistance against animal bites and scratches. Additional agricultural OSHA regulations specify cut-resistant linings in livestock equipment. But lack of global standardization has been an issue and testing specification for ASTMs for veterinary gear is different than an ISO for law enforcement. Nevertheless, 81% of all manufacturers focusing on R&D still value standardization and harmonization. They are anticipated to be allianced occupational safety systems in the matter of bite protection by the year 2026. With international safety requirements growing, adherence to standards is increasingly essential in the workplace.

Bite Resistant Fabric in Animal Handling and Veterinary Fields

Bite resistant textiles are required in animal handling, veterinary and the like where workers are repeatedly exposed to bites and scratches. In high-risk facilities, the Veterinary Safety Institute (2023) also noted 34% decrease in workplace injury with the implementation of bite-resistant equipment. These developments simultaneously provide protection and mobility, while adhering to hygiene regulations in clinical settings.

Livestock Management Gear Reinforced with Bite Protection

For livestock handlers, gear that can withstand the bites of cattle, sheep and other large animals, without limiting movement, is essential. Newer designs now combine synthetics such as Dyneema® with metal like stainless steel mesh to achieve puncture resistance and maintain a lighter gear weight (<12 oz/sq. yd). Brittle reinforced arm sleeves in dairy farms reduced bites related injuries by 58% in a 2022 case study. Leading manufacturers prioritize:

- Breathable laminates to prevent heat stress

- Ergonomic stitching to avoid chafing during prolonged use

- Quick-release systems for emergency scenarios

These advancements align with the 2024 Farm Safety Guidelines, which mandate bite-resistant materials in high-risk agricultural operations.

Veterinary Surgical Gloves Integrating Cut-Resistant Layers

Veterinary gloves now incorporate UHMWPE fibers to protect against bites during procedures while maintaining tactile sensitivity. A 2022 study in the Journal of Veterinary Medicine found that gloves with UHMWPE layers reduced perforation rates by 41% compared to standard nitrile gloves. Key innovations include:

- Double-layer designs: A soft inner layer cushions hands, while an outer cut-resistant sheath deflects teeth and claws.

- Antimicrobial coatings: Silver-ion treatments minimize infection risks in bite-prone wound care scenarios.

- Extended cuffs: 8-inch gauntlet styles prevent saliva or blood from entering gloves during dental or surgical work.

Facilities using these gloves reported a 29% drop in post-bite infection rates (Veterinary Infection Control Network, 2023), demonstrating their dual role in staff safety and patient care.

Law Enforcement Applications of Bite Resistant Gear

Law enforcement also third finger which are vulnerable to bites particularly during k-9 operations and civil unrest. Today’s bite-proof fabrics easily integrate into protective garments, reducing work-related incidents more than 70% in high-risk units (Field, 2024). These materials have both the benefits of cut resistance and the ability for biomechanical impact dispersion (freedom of movement) with an effect that bite penetration dangers are minimized freely.

K-9 Unit Bite Suits Reducing Occupational Injuries

Injuries to K-9 handlers during training exercises decreased by 84% following implementation of tri-layered, synthetic materials into bite suits. These suits include shear-thickening fluids sandwiched between aramid fiber weavesâstiffening as soon as it reacts to a bite and then returning to flexibility after the bite is removed. Ventilation channels eliminate heat stress during long drills, and injury rates have fallen to 2.3 per 100 officers yearly from 14.7 before the system was implemented.

Riot Control Uniforms with Multi-Threat Protection

Contemporary riot gear addresses bite attacks as part of integrated threat matrices. Sleeves and collars are reinforced by polymer-coated chainmail substrates, stopping bites without compromising slash or blunt-force protection. During urban deployment simulations, suits withstood canine forces exceeding 1,500 PSI while maintaining full articulationâcritical when responding to combative subjects.

Market Dynamics for Bite Resistant Clothing

The bite-resistant clothing market has grown 18% annually since 2021, driven by stricter safety protocols and a 40% rise in animal-related workplace injuries. Recent analysis from the 2024 Protective Apparel Market Report reveals 72% of manufacturers combine UHMWPE with stainless steel mesh for optimal flexibility and bite resistance.

Three disruptive trends are reshaping the industry:

- Sustainability shifts: 58% of new products incorporate bio-based fibers like spider silk analogs.

- Smart integration: Sensor-equipped garments that alert wearers to fabric compromise now account for 21% of premium offerings.

- Regulatory alignment: 14 countries have updated workplace safety codes since 2023 to mandate bite-resistant PPE in animal-handling roles.

North America dominates with 45% market share due to advanced manufacturing ecosystems, while Asia-Pacific emerges as the fastest-growing region (26% CAGR) driven by expanding petcare industries and snakebite prevention initiatives. The sector’s projected $3.4 billion valuation by 2028 underscores its critical role in modern protective solutions.

Future Trends in Bite Resistant Textile Innovations

Sustainable materials and intelligent technology is shaping up future bite-resistant fabric. Eco-conscious hybrids of natural materials and recycled synthetics help reduce the impact of our footprint, yet are not short on protective factors. There are additional microscopic sensors that track fabric tensile load and puncture threats, which give instant new safety output while in the midst of the more risky interventions.

Nanotechnology and bio-engineered fibres are the next frontier in material improvement. They deliver true lightweight fabrics with enhanced tearing strength, resistance to penetration and thermoregulation with greater comfort and flexibility. The result is versatile apparel that offers layered protection from bites, cuts, scratches, and external threats all in one package. In addition to functionality, the combining of safety criteria with stylish design is a turning point toward the consumer in terms of aesthetics, facilitated by hyper-personalization at the consumer end with e-commerce and collaborative industry certifications to back up performance claims.

FAQ

What are bite-resistant fabrics used for?

Bite-resistant fabrics are used in various high-risk industries such as animal handling, veterinary fields, and law enforcement to provide protection against bites and scratches.

How do bite-resistant fabrics work?

These fabrics work by using advanced polymer chemistry, molecular orientation, and fiber-to-fiber bonding to disperse impact force and provide puncture and tear resistance.

Are bite-resistant fabrics included in any regulations?

Yes, many regulatory bodies worldwide, including OSHA and EU-OSHA, mandate the use of bite-resistant fabrics in occupational settings with animal exposure.

What advancements have been made in bite-resistant textiles?

Recent advancements include using synthetic fiber blends, integrating smart sensors, and adopting bio-based fibers for improved durability, sustainability, and protection.

What sectors are driving the growth of the bite-resistant clothing market?

The market growth is driven by sectors such as agriculture, law enforcement, and veterinary services, with North America and Asia-Pacific being key regions.

EN

EN