Aramid Fabric: The High-Performance Material You Need to Know About

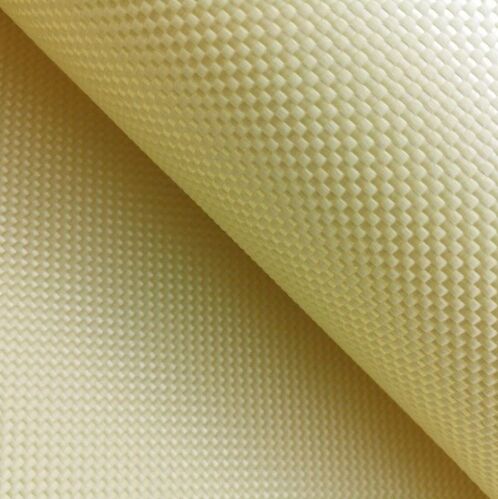

Understanding Aramid Fabric

Aramid fabric belongs to a class of synthetic fibers prized for their exceptional properties, which explains why they're so widely used in protective gear and across many industries. What makes these materials stand out is their incredible strength combined with heat resistance and long lasting durability. They really shine in situations where people need protection against harsh conditions or potential hazards. We see aramid fabrics everywhere from airplane components to military equipment, not to mention fire departments relying on them for turnout gear. Even regular industrial workplaces stock up on aramid products because worker safety simply cannot be compromised.

The aramid fiber family basically splits into two main categories: Para-aramid and Meta-aramid, both serving different purposes across various sectors. Take Para-aramid for instance, Kevlar being the most well known example. What makes this stuff stand out is its incredible tensile strength and ability to withstand damage, which explains why it shows up so much in body armor and aircraft components. On the other hand, Meta-aramid fibers like Nomex focus more on heat resistance characteristics. Firefighters rely heavily on these materials because they can handle extreme temperatures without breaking down, which is why we see them in turnout gear and industrial protection suits. These distinct material properties mean manufacturers can select the right fiber depending on what their particular application requires, whether it's impact resistance or thermal protection.

Key Properties of Aramid Fabric

Aramid fabric stands out because of how strong it is compared to its weight, which makes it perfect for tough jobs like stopping bullets or resisting cuts. Some tests show this stuff can actually be around five times tougher than steel when they weigh the same amount, giving wearers incredible protection without adding bulk. Take a look at what happens in the field too – aramid goes into things like body armor and headgear where people need to stay safe but still move freely. Firefighters, police officers, even workers on construction sites rely on these materials daily because they know their lives depend on them holding up under pressure.

Aramid fabric stands out because it resists both heat and flames, which is why many people choose it for making fire resistant clothing. Some types of aramid fabric can actually handle temperatures reaching around 600 degrees Fahrenheit before they start to break down. These materials won't melt or drip when exposed to extreme heat either. The NFPA backs this up, stating that aramid's ability to resist flames makes it essential equipment for firefighters and workers in industries where sparks fly regularly. We see these fabrics in everything from turnout gear worn by emergency responders to protective suits used in steel mills and chemical plants daily.

Aramid fabric stands up well against chemicals and keeps its shape even when things get tough. This means it doesn't break down easily in different environments, making it really important for places like aircraft manufacturing and car production where materials need to survive extreme conditions. For instance, parts made from aramid can handle exposure to fuels, oils, and other corrosive substances without losing strength. Because these fabrics retain their original qualities for so long, they find their way into all sorts of applications beyond just industrial settings. From protective gear worn by workers to components inside machinery, aramid delivers consistent results year after year without letting users down.

Applications of Aramid Fabric

Aramid fabric is really important for protective gear worn by people working in dangerous jobs. Firefighters wear it in their turnout gear, law enforcement officers put it in body armor, and soldiers incorporate it into combat uniforms because it combines durability with a surprising amount of comfort. What makes this material stand out is how tough it actually is yet still light enough that workers can move around without feeling weighed down. This balance between protection and mobility matters a lot during emergencies when every second counts and personnel need to stay agile while staying safe from burns, cuts, and other workplace dangers.

What makes this material so important goes way beyond just keeping people safe. Industries across the board are finding new uses for it, especially in cars and planes where reliability matters most. Take aramid fibers for instance they're used all over in tire production and airplane parts because they hold up when things get really hot or cold. The stuff is surprisingly light but still super tough, which means manufacturers can build vehicles that weigh less without sacrificing strength. This translates to better handling on roads and runways, plus those lighter vehicles burn less fuel too, saving money at the pump and cutting down emissions in the process.

Aramid fabric has become a go to material across construction sites and industrial settings because it just doesn't break down easily. Builders commonly use this stuff for insulating walls and reinforcing structural components inside buildings. The fabric stands up really well against all sorts of tough conditions including exposure to aggressive chemicals and extreme temperatures. Structures built with aramid tend to hold together much longer between needed repairs or replacements. Many engineers now consider aramid an essential part of their toolkit when designing durable infrastructure that needs to last decades without constant upkeep.

Care and Maintenance of Aramid Fabric

Keeping aramid fabric in good condition requires following some basic care rules. When washing, stick to a gentle cycle with cold water and regular laundry soap works fine. Don't use fabric softener or chlorine bleach though since they tend to break down the fibers over time. For drying, best bet is to let it air dry naturally. If absolutely necessary, a tumble dryer on the lowest heat setting will work but nothing hotter than that. The high temperatures really mess with the material's strength and protection properties which is why most manufacturers recommend avoiding them altogether.

Storing aramid fabrics correctly really matters if they need to last long term. Store them somewhere cool and dry to stop moisture from collecting inside, since this will eventually make the fibers weaker. Don't leave them out in direct sun for too long either because those UV rays actually break down the material, making it less effective at what it's supposed to do. When people follow basic storage guidelines like these, the protective qualities and durability of aramid fabrics stay intact, so they keep performing well even when used in tough industrial settings where failure isn't an option.

Featured Product: UD Ballistic Aramid Fabrics

UD Ballistic Aramid Fabrics are engineered for those seeking maximum protection without sacrificing comfort. By utilizing advanced materials, these fabrics offer a balance of lightweight construction and heavy-duty safety. They are designed with cutting-edge technology to provide exceptional ballistic protection, making them an ideal choice for high-risk environments.

Key features of UD Ballistic Aramid Fabrics include their high tensile strength, flexibility, and validated effectiveness in ballistic protection. These qualities have been rigorously tested by leading safety material laboratories, ensuring their reliability in critical situations.

The application spectrum of UD Ballistic Aramid Fabrics is vast, as they are used in essential protective gear such as bulletproof vests and armored vehicles. Their role in ensuring personal and vehicular safety cannot be overstated, showcasing their importance in the field of protective solutions.

The Future of Aramid Fabric

The aramid fabric sector looks set for some major breakthroughs thanks to new tech developments. Scientists working in this field are looking at ways to make the manufacturing process better so fibers become stronger without costing as much to produce. Stronger materials mean better performance from these fabrics, plus they'll be affordable enough for lots of different uses beyond just military or industrial settings. New innovations are also helping manufacturers cut down on waste and energy usage during production. As consumers get more concerned about environmental impact, these greener approaches will definitely boost demand for aramid fabrics across many markets.

- Innovations in Manufacturing: Technological innovations are enhancing manufacturing processes.

- Cost Reduction: These advancements are making aramid fabric production more cost-effective.

- Sustainability: New methods promote environmentally friendly practices.

Aramid fabrics aren't just stuck in their old roles anymore. Some folks in the industry think we might see them showing up in places we never imagined before. Take wearable tech for instance these days people are talking about putting these materials into things that actually work with electronics. Imagine clothes that can track your health metrics or something like that. And then there's the whole area of composites where aramid fibers could make stuff both stronger and lighter at the same time. This matters a lot for planes and cars where weight savings translate directly into fuel efficiency gains. Research keeps pushing forward on all fronts which means aramid isn't going anywhere anytime soon. Manufacturers who stay ahead of this curve will find themselves with plenty of fresh markets to explore as the material continues evolving alongside our technological needs.

- Wearable Technology: Aramid fabrics might become a crucial component in wearable tech.

- Advanced Composites: Their incorporation in composite materials is anticipated.

- Research Developments: Ongoing research is crucial for unlocking these potential applications.

FAQ

What are aramid fabrics commonly used for?

Aramid fabrics are commonly used in protective clothing for firefighting, military, and police applications, as well as in industrial safety gear, automotive, and aerospace components.

How do aramid fabrics provide protection?

Aramid fabrics provide protection through their remarkable strength-to-weight ratio, heat and flame resistance, and chemical stability, making them ideal for use in environments exposed to extreme conditions.

Can aramid fabrics withstand high temperatures?

Yes, certain aramid fabrics can withstand temperatures up to 600°F, maintaining integrity without melting, making them suitable for fire-resistant clothing.

How should aramid fabrics be cared for?

Aramid fabrics should be machine washed on a gentle cycle using cold water and mild detergent, avoiding fabric softeners and bleach. They should be air-dried or dried with low heat to preserve their structure and effectiveness.

EN

EN