Man, you can't do without abrasion resistance fabrics in the manufacturing and industrial worlds. When we think about the things factories and companies make, we imagine shiny machines and big pieces of equipment. But behind all of that, there are textiles suffering daily abuse! These fabrics are used to make things like uniforms, protective equipment and machinery covers. That in turn means they hold up better and thus do a better job. We are dedicated to supplying the best abrasion-resistant materials, industry professionals can depend on. Our materials are not only durable, they offer the safety and efficiency that’s necessary in these environments. If you’re wondering why these fabrics are so significant, let’s break it down a bit.

Simplifying the Functionality of Abrasion Resistant Textiles within Industrial Applications

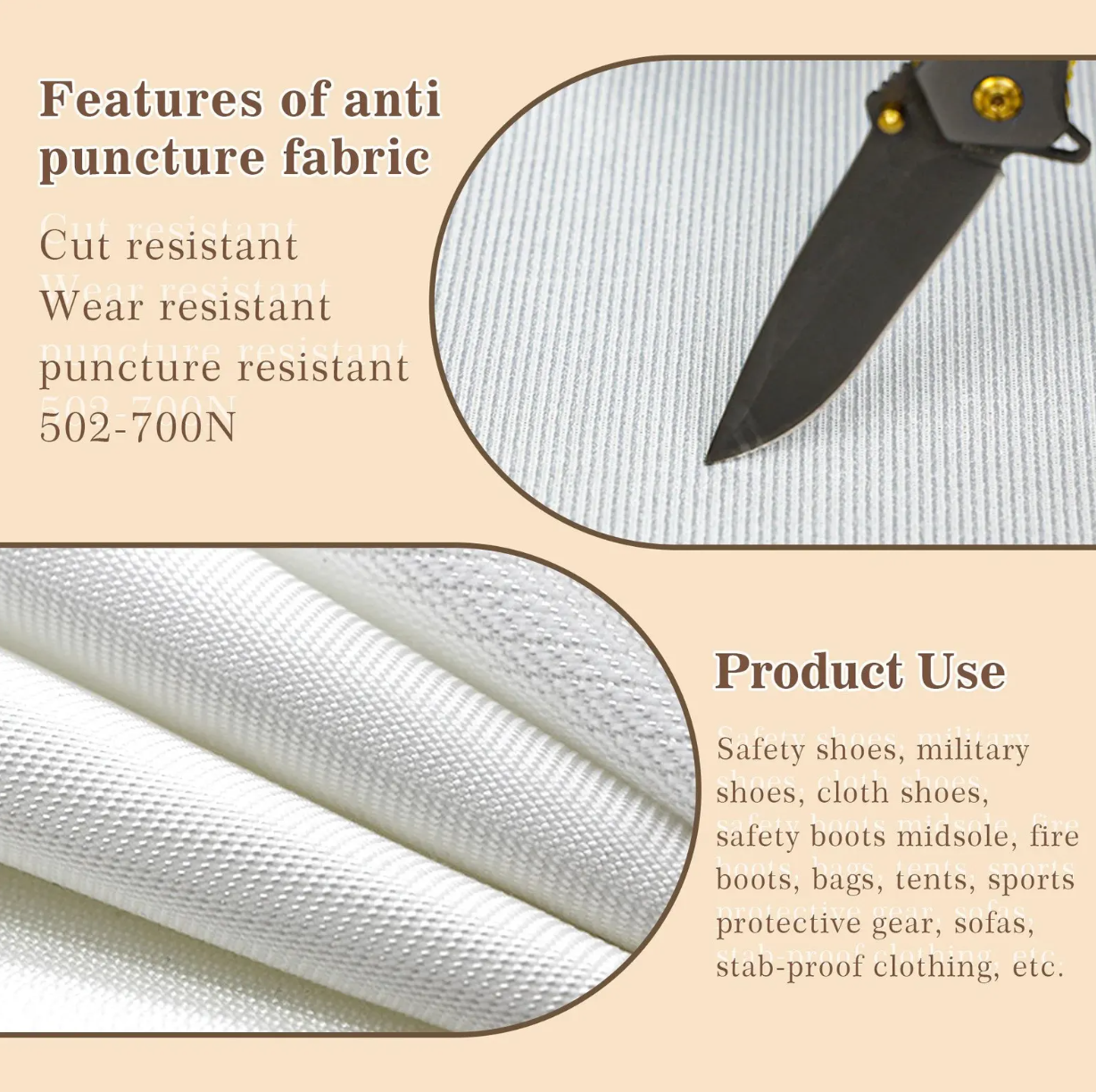

Abrasion resistance fabrics have a unique role in the production. They protect workers from harm, and that’s a big deal! For instance, a factory worker might wear clothes made of these sturdy fabrics to shield themselves from sharp objects or rough surfaces. Think about it! Other jobs are in the vicinity of machines that can easily catch or rip regular clothing. Body armour made with cut-resistant fabrics can also help minimize risks from cuts. They are also used to wrap valuable machines. The cover can become scratched or worn down, which could cause the mechanism to stop functioning correctly. And that’s why your fabric choice is crucial! In the case of our production at Nize, we test out materials and make sure they can hold up under harsh conditions (such as heat and humidity) without falling apart. Nowhere is this truer than it is in construction or manufacturing. There, every detail makes a difference! High resistance safety gear and uniforms make sure that workers focus on their jobs no on concern for the clothes.

What's more, these fabrics are part of sustainability. Durable products require less waste, and take on an importance for our environment. When teams utilize gear that is built to last, fewer resources are consumed in the long run. Consider how many uniforms get tossed out every year when they fade and tear so easily! Better textiles can help minimize that. This connection between smart materials and being environmentally friendly is a value we really strive hard to push at Nize. We work hard to make stylish, great quality products available to everybody. So, when you choose to wear or use abrasion-resistant fabrics, you’re not just snagging something that’s brawny; you’re also helping the planet.

Selecting the Ideal Abrasion Resistant Fabrics for Your Wholesale Needs

Selecting the right abrasion resistant fabric is not always an easy task, but it’s a very important one, especially when you are purchasing on behalf of a business or organization. The first thing you have to consider is what type of work the fabric will be doing. Different jobs call for different levels of toughness. If you are supplying a factory that is dealing with machinery, you may need heavier fabrics which can not tear easily. But if you are shopping for uniforms with which to outfit your staff, you may want fabrics that not only put abrasion in its place but also feel good when they are against the skin.

Second, think about where this fabric will be used. Will it have exposure to chemicals, sun or moisture? For instance, if the workers are going to be outside a significant amount, they need materials that can stand up to sun exposure without fading and wearing. Enter Nize, the world’s foremost expert on the art. All of our fabrics are engineered to answer such requirements so that customers would not encounter the frustration of selecting for the wrong material. And you may want to consider how easy it will be to clean fabric, too. Some can get really dirty, and if they are easy to wash, win!

And finally, consider the fabric’s appearance too! It’s not all about how rugged it is; sometimes, you also want a good design or color. Your team should look good in what they put on. At Nize we supply a variety of options to have you looking professional and safety conscious. So, when choosing textiles always consider the job expectations, environment, how easy they’ll be to care for and of course their aesthetic. All fabrics, all things considered fit and durable in terms of quality-Yes you think about these when browsing for the right fabric.

Why You Need Abrasion Resistant Fabric For Superior Quality Processing

As textiles suitable for casement curtains. These are simply cloth fabrics that resist abrasion. In a lot of industries, the clothing and items that we use should stand the test of time. “When they wear out too fast it can really add up,” he explained, “because the replacements are something we have to buy frequently. That's where the abrasion resistant fabrics are put to use. This fabric is closely woven, or, made of particular stuff which will bear rubbing; it behaves stiff against the nails. These sturdy textiles are used when constructing goods so you can be sure your product will stand the test of time. This is particularly significant in industries such as construction, automotive and outdoor gear, where products take a beating.

Think of slipping on a pair of gloves while working in the yard. If your gloves aren’t hardy, they could rip. If they are constructed with abrasion resistant fabrics however, they will outlast and protect your hands. The logic is the same for tools, bags and other manufacturing items. Businesses like Nize specialize in manufacturing such materials for high quality products and so that businesses can cut costs and give their customers better items. Sure, when products are made from sturdy materials they tend to look nicer and perform their function better over a longer period of time, all things that keep people satisfied and returning for more.

One other significant factor to use abrasion resistance fabrics is safety. Often, workers want clothes or equipment that does not come apart easily, particularly if they are dealing with sharp instruments or dangerous machines. The use of durable fabrics decreases the risk of accidents and injuries. This is especially critical at factory and field sites that require safety measures. Furthermore, organizations that produce high-quality textiles can also demonstrate to their customers they value giving the best products. So, the use of abrasion resistant fabric is not only a smart business move, but a sound investment in safety and worker satisfaction during production.

Where to Locate Leading Suppliers of Abrasion Resistant Fabrics for Wholesale

Finding a good manufacturer of abrasion resistant fabrics is no small matter, especially if you want to buy in large quantities. You might consider looking into a company such as Nize, which makes some of the best and toughest textiles around. As you search for a quality manufacturer, consider their status and what materials they use. You can conduct searches on-line, read reviews and even request for samples to see the quality of the fabrics yourself. Most manufacturers will have websites where you can learn about their fabrics and even show how strong their textiles are compared with others.

Going to industry trade shows and expos is another amazing way to meet manufacturers face to face. Here, you can actually see and try out the products that are being created and you can even talk to the people who make them. This is to help you learn more about the different fabrics, and to make a connection with the manufacturer. It’s crucial to ask questions, such as what materials are being used and how long the textiles will last in different conditions. Also, see if they can offer you a bespoke product. There are some manufacturers that offer to make the fabrics in other colors or styles, which can be handy if you’re going for a specific look with your products.

Finally, speaking with other businesses can be helpful as well. If you have a friend who works in your industry, feel them out about where they source their textiles. Some of the best suppliers are found through word of mouth. Make with a partner that specialises in abrasion resistance Nize Here at Primo, we are experts when it comes to quick-release pins.

The Many Benefits of Abrasion Resistance for Your Industrial Products

Weaving with abrasion resistant textiles is one of the most intelligent, effective ways to get more life out of your industrial products. They’re built to withstand rugged conditions, so they don’t die out quick. When something is made with durable materials, it means that you can use it daily without a thing falling to pieces. Let’s take safety gear such as gloves or protective clothing, for instance. The higher the abrasion resistance of those materials, the less they tear. This not only protects workers, but also can help businesses avoid having to purchase replacements as frequently.

In addition, when you select high-end fabrics for your products, you can also boost customer satisfaction. Customers like things that last, and are more likely to come back for more if they know your products will stand up well over time. This can result in higher sales and a better branding for your business. Nize’s wear resistant fabrics offer a solution for both manufacturers and consumers in mind.

Plus you're recycling while saving on resources and waste. And if our things last longer, that means we use fewer things in the long run. This is good for the environment, and it also helps companies hold down costs. Companies with quality textiles can have a positive impact through sustainable business practices. After all, choosing abrasion resistant textiles can be a win-win for companies and their clients alike the products created will end up being strong, safe and reliable over years of use thanks to that early decision made to invest in quality textile technology.

Table of Contents

- Simplifying the Functionality of Abrasion Resistant Textiles within Industrial Applications

- Selecting the Ideal Abrasion Resistant Fabrics for Your Wholesale Needs

- Why You Need Abrasion Resistant Fabric For Superior Quality Processing

- Where to Locate Leading Suppliers of Abrasion Resistant Fabrics for Wholesale

- The Many Benefits of Abrasion Resistance for Your Industrial Products

EN

EN