Puncture-proof fabric is super important for a working man that needs durable protection in his not so friendly job. At Nize, we develop these robust materials to protect people from any kind of danger. One injury can be catastrophic if you work in a high risk environment. That’s why the proper gear is all-important. Our puncture-resistant fabrics are engineered to be tough and offer workers peace of mind. This article discusses how these textiles can deliver a significant safety improvement and why they are necessary in environments where danger is lurking around every corner.

Puncture-Proof Materials for Safety in Industrial Environments

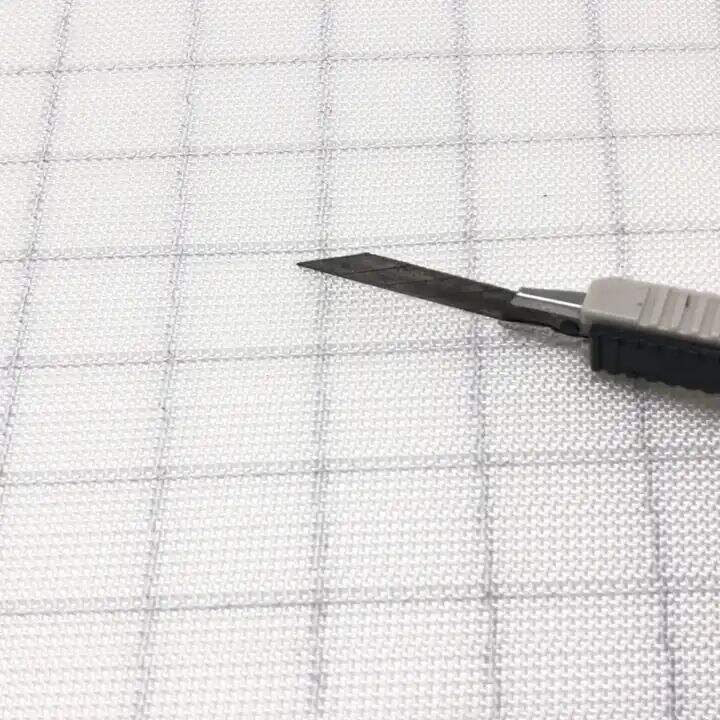

Risks go hand in hand with many industrial professions. Slicing and Boring Sharp instruments, heavy machinery, or rough terrain can cause cuts or puncture wounds. They aim to minimise these hazards by using puncture-proof materials. Take the case of a factory worker working with sharp objects, for instance. If they have on non-fabric gear, they could easily injure themselves. But puncture-proofing fabric from Nize dramatically reduces the likelihood of those injuries. These materials have tough protective coatings that make it difficult for sharp objects to penetrate.

If workers are more comfortable in their gear, they can be more focused on the job. That means they operate more quickly and efficiently. They have confidence that comes from the comfort of knowing their clothes can take what life surprises them with. Punctures-proof shirt or gloves can provide them with the extra protection. And that’s significant not only for the worker, but also for the company. The fewer injuries, the less time that would be missed for healing and the fewer medical bills. When you invest in good protective gear like what we have here at Nize, ultimately it will save you time and money.

It’s also important to foster a safer culture in the workplace. When workers see that their company cares about keeping them safe by offering solid gear, it means a lot. This has the potential to foster teamwork and a positive environment. Holes and tears on flimsy fabrics aren’t just some minor annoyance; they can lay workers open to danger! They work behind a barrier of puncture-proof material that will keep harm at bay.

Why Do you Need Puncture proof fabrics for Hazardous Work Conditions?

Workers need the best fabrics available on jobs that are inherently dangerous, like construction or manufacturing. The top choices are materials that can’t be punctured. Why? As they are able to take the rough times. For example, a mechanic working on equipment may need to be under the equipment and exposed dangerous enamel edges. Pants made of heavy fabric help them withstand sudden scrapes or jabs.

Here at Nize, we strive to bring you heavy duty materials that aren't just durable but also comfortable to wear. Protective apparel should not hinder workers’ freedom of movement. Typical materials are cumbersome or difficult to work with. Our puncture-proof fabrics balance safety with comfort, so workers don’t have to sacrifice safety for freedom of movement. This comfort can inspire workers to wear their protective gear all day, that’s the goal.

Puncture-proof also protects against other types of damage, as well. They are frequently built to resist tearing, so they last longer. Not only is this a cost effective, but has the advantage of continued immune protection over time. In settings where every second matters, you want to be confident that your gear won’t fail. It’s like the nurse in a hospital environment who is hassled with potential hazards when you are dealing with sharps. They very well may be putting themselves at risk day in and day out without durable, puncture-proof clothing.

Let’s face it, in dangerous work conditions you need the right equipment. Puncture-proof material also ensures wearers are protected from serious injuries when working. At Nize, we understand what safety means and take responsibility in continuing to provide durable and reliable solutions that power through tough conditions. When the focus is safety, all parties win!

Selecting Puncture-Proof Fabrics for Your Business Requirements

When choosing puncture resistant fabric to use in your company you need to think about what exactly you actually need. First, consider the type of work of your team. Do they use sharp tools, heavy machineries or any other material that would just bring havoc to regular fabrics? Yes, then you require tough and puncture resistant cloth. Appropriate fabrics will be used to make sure that your workers are comfortable and safe. The weight of the fabric will be another thing that you will want to consider. Better resistant to punctures, though often heavier and robust, are materials that are thicker. You desire something of power and ease.

Fabric breathable is another thing that I would consider. When the employees work long hours, they would like to be able to get cool and not to get too hot in case of wearing heavy clothes. In this aspect, air-permeable fabrics may be of use. Another issue worth taking into consideration is whether the material is waterproof or something that cannot be affected by chemicals. Other jobs require dealing with liquids that can ruin normal clothes. Lastly, acknowledge the reviews or add suggestions on some puncture-resistant clothes. On the products aspect, there are also companies that focus on the manufacturing of high quality materials, such as Nize, so one should know what brands to rely on in order to get a good product.

And do not forget about the safety standards! Commercial operations have some that require specific protective cloth safety ratings. Ensure that the fabric you are using that is puncture proof meets these requirements. The most important thing is the safety of your workers and high-quality fabrics represent a significant component of that. And when you make the right choice, you are creating a safer work environment that will enable your employees to concentrate on the work, but not safety. You are also investing in the health and productivity of your workforce, when you invest in the quality of puncture-proof fabrics.

What New Technologies are Behind the Shift Towards Puncture-Proof PPE?

Puncture proof PPE designs are becoming possible through state-of-the-art designs in this era. Firms should be provided with superior protection wearable to ensure workforce safety in hazardous jobs. One of the great innovations is the application of new types of fibers and blends which are far more durable as compared to the old material. These more modern materials are able to withstand sharp objects and they too are light and stretchy. This will enable the workers to move around more easily, as they never feel burdened. An example of this is at Nize where we are always experimenting with new fabrics, which are both comfortable and safe.

The other segment to follow is smart textiles or advanced fabrics that do not simply protect. Some of them are capable of changing color depending on the temperature or even monitoring the vital signs of the worker, including heart rate. These advances make PPE a smarter and safer product. Companies are also becoming aware of the fact that they attract more employees. Employees prefer the modern equipment that is sophisticated and more comfortable.

More so, it is true environmental sustainability is a trend. More and more enterprises would like to work with the materials that do not destroy the planet. Firms are currently searching recycled materials that have eco-friendly puncture-proof materials. These types of fabrics would serve to lower wastes but at the same time provide protection to the workers. And as even more individuals start to realise the climate change reality that our world is facing, they start appreciating greener options. Nize is also trying to keep up with the trend and produce eco-friendly products without compromising on safety and quality. All of these innovations are not only related to safety, but they are all an indication that companies not only care about their employees but also about this world.

Comparison between Puncture-Proof Fabrics and Traditional Materials in Industrial Applications

When we put puncture proof materials against ordinary ones then it is quite obvious that the puncture resistant fabric ones have a very practical benefit. There are some fabrics, including cotton or polyester, which are comfortable, but they will not resist sharp objects. In case a worker accidentally stabbed the sharp tool or a piece of metal which pricked him, it is possible that the fabric which is generic tears easily and this is not safe. Cut resistant Pinch and cut resistant Puncturing Puncture-proof materials are designed to resist puncture and cutting, which is of an essential benefit when working on the job and being prone to be harmed easily.

The other difference is durability. The above old-school fabrics can wear out quickly when they come into contact with the harsh working conditions. Puncture-resistant fabrics, on the other hand, are produced to be useful with a more extended duration of time. Such durability implies that in the long term, companies will be able to save by not having to purchase protective clothes as often. It is also free to the environment in that it produces less waste during less frequent replacement.

Tear resistant materials are also normally much tighter as compared to the bullets in nature. Besides that, even where protection capability is offered to conventional material, it might lack in chemical resistance or heat and water resistance. This is experienced by employees in heavy-duty workplaces - factories or construction sites. Puncture resistant textile materials are offered including those of Nize. These materials can be tailored to handle these rough environments and aid in safeguarding workers to make them safe and comfortable at the workplace.

Though traditional fabrics are good for every day wear and some minor chores puncture proof materials offer safety and long-lasting performance. Puncture-proof materials aren’t just keeping pace with the modern workforce they are enabling workers to do their jobs without having safety on the brain. That’s why in today’s day and age, you can not afford to use less than the best puncture-proof fabrics there are!

Table of Contents

- Puncture-Proof Materials for Safety in Industrial Environments

- Why Do you Need Puncture proof fabrics for Hazardous Work Conditions?

- Selecting Puncture-Proof Fabrics for Your Business Requirements

- What New Technologies are Behind the Shift Towards Puncture-Proof PPE?

- Comparison between Puncture-Proof Fabrics and Traditional Materials in Industrial Applications

EN

EN